What is Military PCB?

Home < Military PCB < What is Military PCB?

2022-12-29 16:57:19 Military PCB 348 Viewed

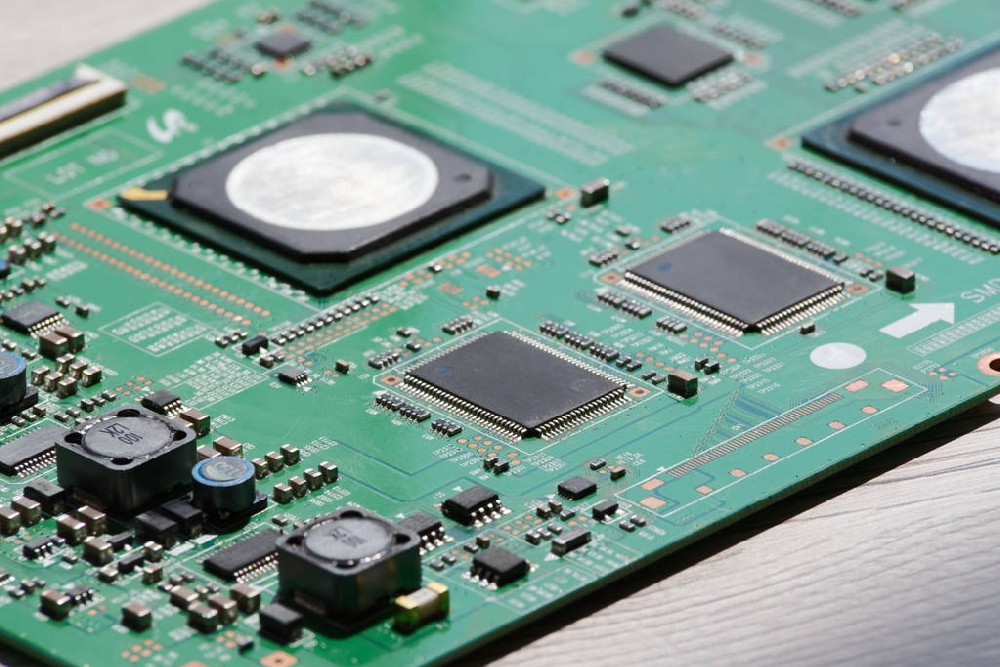

SummaryAviation and military PCBs are often subject to harsh environmental conditions which include elevated/fluctuating temperatures, extreme humidity and humidity, etc. Also, aerospace and military PCBs are often exposed to harsh chemicals, hydrocarbon solutions, dust, and other contaminants. High-qualit...

Aviation and military PCBs are often subject to harsh environmental conditions which include elevated/fluctuating temperatures, extreme humidity and humidity, etc. Also, aerospace and military PCBs are often exposed to harsh chemicals, hydrocarbon solutions, dust, and other contaminants. High-quality materials are required for aerospace and military PCBs to withstand harsh conditions in military and aerospace applications.

Designing and manufacturing military PCBs requires special attention to durability and compliance. All components must be able to withstand the harsh environment. Military PCBs should meet MIL specification grade standards and pass the highest performance and functional tests. General considerations for military PCBs include:

Military PCBs should handle the maximum current load. There should be a clear distinction between low frequency and high frequency components. For example, certain high-frequency components may produce waveforms that affect low-frequency components. These waveforms add noise and degrade signal quality. For the military, this is unacceptable.

All clock signals on military PCBs should be clean and shielded. In order to make the current transmission smooth, all the wiring of the military PCB should maintain a 45° angle or less. Finally, all military PCBs should be manufactured in strict accordance with MIL-PRF-50884, MIL-PRF-55110, and MIL-PRF-31032 standards.

Military PCB Material

After being familiar with the design requirements of military PCBs, the materials for designing and manufacturing military PCBs should also be considered. Military-grade electronics are often used in harsh conditions, including high temperatures. Military PCBs should withstand and perform at a high level even under these conditions.

If heat dissipation is required, thermal paste should be used. At this stage, an in-depth understanding of the different composite materials, substrates, and elements used in military PCBs is invaluable. They must meet specific rigidity, flexibility, electrical and thermal requirements to be considered military grade. Some of the best materials for military PCB boards are: aluminum, copper, high temperature laminates, etc.

Test Methods and Precautions for Military PCB

Test inspection is essential to confirm the reliability and durability of military PCBs in real-world applications. For military PCBs, the MIL-STD-202 standard is the basis for all electronic product test methods. After the military PCB satisfies the design of manufacturability considerations, various tests can be performed, including:

X-Ray Inspection – Also known as AXI, this test checks for various defects such as solder connections, barrels, and internal traces before military PCBs go into full-scale manufacturing.

Functional Tests — The ancient functional tests check that military PCBs will power up. How functional testing is performed depends on the application.

Various other tests can also be performed on military PCBs, including: solderability test, PCB contamination test, time domain reflectometer (high frequency board), solder float test, etc.

Reliability of Military PCB

The reliability of military PCB is that it can perform its function and performance normally, accurately and stably. There are many factors that affect the reliability of military PCBs, and the following requirements should be considered:

1) Military PCBs use common materials and popular processing techniques as much as possible;

2) The design of military PCB should be simple, symmetrical in structure and uniform in layout;

3) The number of layers of the military PCB should be as small as possible, and the diameter and aperture of the land, the width and spacing of the wires should be as large as possible;

4) The thickness-to-aperture ratio of military PCBs should be as small as possible, generally not greater than five to one.

Previous:没有了!

Military PCB Description

military PCB, military PCB manufacturer, military PCB assembly, military PCB board

Military PCB standards

Military PCBS should meet MIL specification grade standards and pass the highest performance and functional tests. Military PCBS are designed and manufactured with special attention to durability and compliance. All components of a military PCB must be able to withstand harsh environments.

Characteristics of military PCB

Military PCBs are designed and tested to withstand harsh environments. Military PCB has the characteristics of high temperature and high pressure resistance, moisture proof, high and low frequency sensing ability, military PCB has excellent transmission clarity and strength, and operates in a corrosive environment.

What is Military PCB? Related Articles

Military PCB Article

Military PCB manufacturers

Military PCB manufacturersMilitary PCB News

Military PCB Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles