Aluminum PCB board contents

Home < Aluminum PCB < Aluminum PCB board contents

2022-11-22 18:11:34 Aluminum PCB 461 Viewed

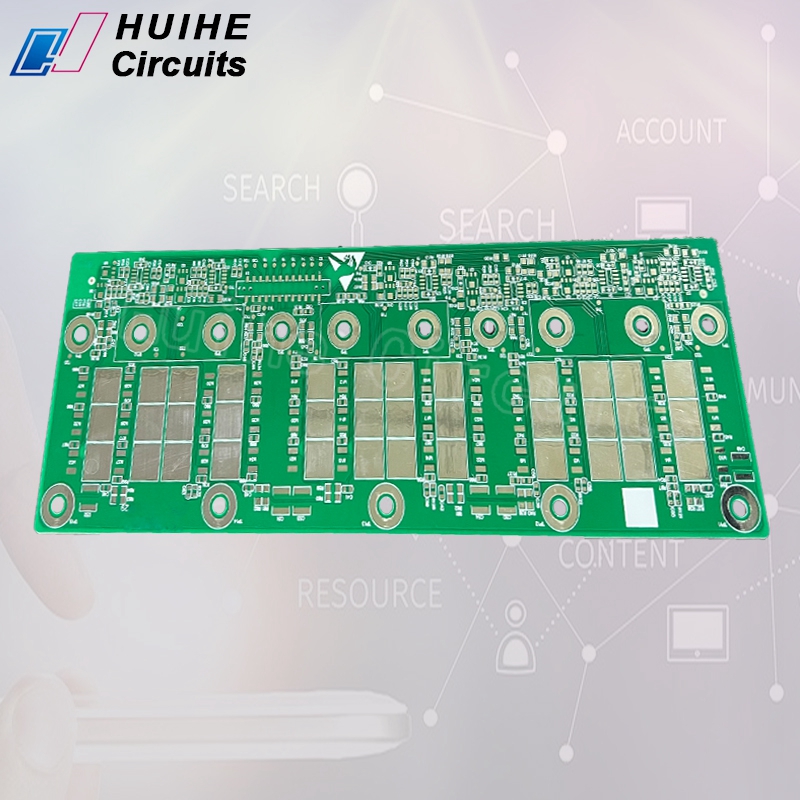

SummaryWhat is an aluminum PCB board? 1. Aluminum PCB Board DefinitionThe aluminum PCB board is a kind of metal base copper-covered plate with great heat dissipation function, which is the basic material of high-power electronic circuit structure technology and interconnection technology. Single-sided alumi...

What is an aluminum PCB board?

1. Aluminum PCB Board Definition

The aluminum PCB board is a kind of metal base copper-covered plate with great heat dissipation function, which is the basic material of high-power electronic circuit structure technology and interconnection technology. Single-sided aluminum PCB board is composed of three layers, which are the circuit layer (copper foil), insulation layer and metal base. Common aluminum PCB board products have LED lighting. There are two sides, the white side is welded LED pin, the other side shows aluminum color, typically will be coated with heat conduction coagulant and heat conduction part contact.

The circuit layer of aluminum PCB board (copper foil) is commonly etched to form a printed circuit, so that each part of the component is connected to each other. In general, the circuit layer requires a large current load, so as to use thicker copper foil, the thickness is typically 35um-280um. The thermal insulation layer is the core technology of aluminum PCB board. It is typically composed of special polymer filled with special ceramics, tiny thermal resistance, great viscoelastic ability, has the ability of thermal aging resistance, can withstand mechanical and thermal stress.

2. Characteristics of aluminum PCB board

Aluminum PCB board can adopt surface mounting skills (SMT).

Aluminum PCB board production in the circuit design of the thermal diffusion is a particularly useful treatment.

Reduce the operating temperature of aluminum PCB board products, improve the power density and reliability of aluminum PCB board products, and extend the service life of aluminum PCB board products.

Reduce the volume of aluminum PCB board products, reduce hardware and assembly costs.

Replace fragile ceramic substrate, obtain better mechanical durability.

3. Working principle of an aluminum PCB board

The surface of the power device on the aluminum PCB board is mounted on the circuit layer. The heat generated during the operation of the device is quickly transmitted to the metal base through the insulating layer, and then the heat is transferred by the metal base so as to realize the heat dissipation of the device.

Compared with the traditional FR-4, the aluminum PCB board can reduce the thermal resistance to the lowest, so that the aluminum PCB board has excellent heat conduction performance; compared with thick film ceramic circuits, it has excellent mechanical properties. Furthermore, aluminum PCB board has the following distinct advantages: meet the requirements of RoHs; they are also suitable for the SMT process.

4. Structure of an Aluminum PCB Board

Line layer

The line layer (commonly electrolytic copper foil) is etched to form a printed circuit for device assembly and connection. With the same thickness and the same line width, an aluminum PCB board can carry a higher current than traditional FR-Insulation layer

The insulation layer is the core technology of aluminum pcb board, and it primarily performs bonding, insulation, and heat conduction functions. The aluminum PCB board insulation layer is the largest thermal barrier in the power module structure. The better the heat conduction performance of the insulation layer, the more conducive it is to the diffusion of the heat generated during the operation of the device, and the more conducive it is to reducing the operating temperature of the device, so as to improve the power load of the module, reduce the volume, extend the life, improve the power output, and serve other purposes.

Metal base layer

The type of metal used in the insulating metal substrate depends on a comprehensive consideration of the thermal expansion coefficient, heat conduction capacity, strength, hardness, weight, surface state, and cost of the metal substrate.

Under normal circumstances, aluminum plate is the best option in terms of cost, technical performance, and other factors to consider. The available aluminum PCB board materials are 6061, 5052, 1060, and so on. If there are higher heat conductivity, mechanical properties, electrical properties, or other special performance requirements, copper plate, stainless steel plate, iron plate, or silicon steel plate can also be used.

5. The purpose of aluminum PCB board

LED aluminum PCB board is commonly seen in LED lighting products, has great heat dissipation function. LED aluminum PCB board is widely used, the following is mainly to introduce the use of aluminum PCB board in detail.

Audio equipment: input/output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier, etc.

Power supply equipment: switch regulator, DC/AC converter, SW regulator, etc.

Communication electronic equipment: high frequency amplifier, filter, transmission circuit.

Office automation equipment: motor drivers, etc.

Car: electronic regulator, igniter, power controller, etc.

Computer: CPU board, floppy disk drive, power supply device, etc.

Power module: inverter, solid state relay, rectifier bridge, etc.

6. Advantages of aluminum PCB board

Aluminum PCB board for various electronic components, integrated circuit provides mechanical support components for fixed electronic components, is to realize the electrical connection of the assembly board.

Heat dissipation: Extreme temperatures will cause serious damage to electronic equipment, so it is necessary to use materials that help heat dissipation. Aluminum PCB boards can transfer heat from vital components to minimize harmful effects on the board.

Environmental protection: aluminum is non-toxic and can be recycled. The use of aluminum PCB board also helps save energy due to its ease of assembly. For PCB suppliers, the use of the metal helps keep the planet active.

Light weight: Aluminum has impressive durability and is a surprisingly light metal. Aluminum increases strength and elasticity without adding any additional weight, and aluminum PCB boards improve the quality and reliability of electronic equipment.

Higher durability: Aluminum provides strength and durability for products that ceramic or fiberglass substrates cannot. Aluminum pcb board is a solid base material that can reduce accidental damage during manufacturing, handling and daily use.

The impact of an aluminum pcb board on an LED radiator

As we all understand, the normal operation of LED has an appropriate temperature condition. If beyond this temperature, the performance of LED will be affected. If you do not control the temperature, it will lose the characteristics of the sustained life of LED lights. Then how to get the heat out of the LED chip? This is the packaging process to do. A lot of practice is to use metal materials at the bottom of the LED package, close to the step of heat conduction, the heat generated by the LED chip to quickly export to the use of aluminum PCB board, that is, not all the aluminum PCB board heat transfer performance are the same? Is it the same to quickly export the heat generated by LED? What is the effect of the heat transfer of aluminum PCB board? Is it the aluminum plate that determines the thermal conductivity of the aluminum PCB board? Let's find out.

The thermal conductivity and speed of the aluminum PCB board are influenced by the structure of the aluminum PCB board. Aluminum PCB board is divided into 3 layers: the first layer is copper berth, the second layer is thermal insulation material, the third layer is aluminum plate. In order to improve the thermal conductivity of aluminum PCB board, the key is to improve the performance of thermal insulation materials. It is not a simple matter to reduce the thermal resistance of thermal insulating materials, which is affected by the material composition and manufacturing process.

At present, there are additional aluminum PCB boards circulating on the market. Its process is coated with a layer of glue on the fiber cloth. Such an aluminum PCB board, its thermal resistance is 1.7 degrees Celsius/W, and some are 3.2 degrees Celsius/W. The thermal resistance is relatively steep, so its heat conduction is not particularly excellent, heat transfer is not uniform, not suitable for high quality, high brightness, high power LED lamps.

With the continuous development of LED chips, the power continues to improve, the heat dissipation requirements are becoming higher and higher, so the aluminum PCB board is also in continuous development. Now the thermal insulation material of aluminum PCB board can be made of whole rubber, through the dust-free workshop, high precision uniform pressing production.

The performance of an aluminum PCB board

The aluminum PCB board is a metal-based copper-covered plate with excellent heat dissipation function. It is a plate-like material covered with copper foil on one side or two sides and made of hot pressing with resin and single resin as an insulating bonding layer. aluminum based copper clad plate, together to understand the performance of aluminum PCB board knowledge.

Aluminum PCB board has excellent heat dissipation performance.

The aluminum PCB board has excellent heat dissipation performance, which is the most prominent characteristic of this kind of board. PCB made of it can not only effectively prevent the load of components and substrate working temperature rise, but also the power amplifier, high-power components, large circuit power switch and additional components of the heat rapidly distributed, in addition to the minor density, light weight, oxidation resistance, inexpensive price and other characteristics. Therefore, it has become the most widely used and the most used composite plate in the metal base copper clad plate.

Improve the efficiency and quality of machines

The aluminum PCB board has great mechanical strength and toughness, which is considerably better than rigid resin copper clad plate and ceramic substrate. It can realize the manufacturing of large area printed board on the metal substrate, especially suitable for the installation of large weight components on this kind of substrate. In addition, aluminum PCB board also has superior flatness, which can be hammered on the substrate, riveted and other aspects of assembly processing or made into PCB along the non-wiring part of bending, twisting, etc., while the traditional resin copper clad plate cannot.

The aluminum PCB board has size stability.

There is a problem of thermal expansion (dimensional stability) for all kinds of copper clad plates, especially the thermal expansion in the thickness direction of the plate (Z axis), which affects the quality of metallized holes and lines. The main reason is that the linear expansion coefficient of the plate is different, the linear expansion coefficient of aluminum PCB board is between, it is considerably smaller than the general resin substrate, and more close to the linear expansion coefficient of copper, which is conducive to ensure the quality and reliability of printed circuit.

Surface treatment of aluminum PCB board materials

Remove oil

The aluminum PCB board material surface is coated with oil layer protection in the process of processing and transportation, it must be cleaned before use, the principle is to use gasoline (generally with aviation gasoline) as a solvent, can dissolve it, and then use water-soluble cleaning agent to remove the oil, with water flushing its surface, so that the surface is clean, do not hang water drops.

Degreasing

After the above treatment of aluminum PCB board base material, the surface has not been cleaned grease, in order to thoroughly remove it, with strong alkali sodium hydroxide in 50℃ soaking for 5min, and then rinse with water.

Alkali corrosion

As the base material, the surface of the aluminum plate has a certain roughness. Because aluminum PCB board material and the aluminum oxide film on its surface are amphoteric materials, the corrosion of aluminum PCB board material can be coarsened by acid, alkaline or compound alkaline solution system. In addition, different substances and accessories should be added to the coarsening solution to achieve the subsequent purpose.

Chemical polishing (dip brightening)

Because aluminum PCB board material contains additional impurities metal, in the coarsening process it is easy to form inorganic compounds adhered to the surface of the substrate, so the inorganic compounds formed on the surface should be analyzed. According to the analysis results, a suitable dipping solution was prepared, and the roughened aluminum substrate was placed in the dipping solution to ensure a certain time, so as to make the surface of the aluminum PCB board clean and bright.

Get Aluminum PCB board contents

Previous:没有了!

Next:Aluminum PCB China

Aluminum PCB Description

aluminum pcb, aluminum pcb manufacturer, aluminum pcb board, aluminum pcb factory, aluminum pcb led, flexible aluminum pcb, aluminum pcb china, aluminum PCB prototyping, aluminum PCB quotes, single side aluminum PCB

Aluminum PCB materials

As the substrate material of the aluminum PCB, the metal aluminum-based copper-clad laminate mainly plays the role of interconnection, conduction, insulation and support for the aluminum PCB, and has a great influence on the transmission speed, energy loss and characteristic impedance of the signal in the line. influences.

Aluminum pcb manufacturing process

Aluminum PCB is a kind of metal copper clad board with good heat dissipation, aluminum PCB can be reduced to the minimum thermal resistance value, so that aluminum PCB has good thermal conductivity, compared with thick film ceramic circuit, aluminum PCB mechanical performance is very excellent.

Aluminum PCB board contents Related Articles

Aluminum PCB board contents Random Article

Aluminum PCB News

Aluminum PCB Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles