What is a 6 layer PCB board?

Home < 6 layer pcb < What is a 6 layer PCB board?

2024-03-22 09:27:19 6 layer pcb 15 Viewed

SummaryWhat is a 6 layer PCB board?The 6-layer PCB board has some unique characteristics and advantages over other layers of PCB boards. First, multi-layer PCB boards can provide higher circuit density because they can fit more circuit layers in a smaller space, which means that designers can fit more func...

What is a 6 layer PCB board?

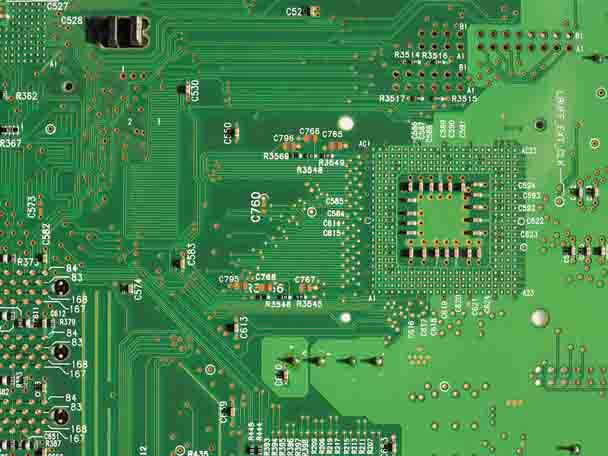

The 6-layer PCB board has some unique characteristics and advantages over other layers of PCB boards. First, multi-layer PCB boards can provide higher circuit density because they can fit more circuit layers in a smaller space, which means that designers can fit more functions and components on the same size board, resulting in more complex circuit designs.

6 layer PCB board is a printed circuit board widely used in the field of modern electronics, which has higher circuit density, better electrical performance and anti-interference ability, and better heat dissipation effect. However, manufacturing costs and design complexity also need to be considered; for applications that require higher performance and more complex circuit designs, 6-layer PCB boards are an excellent solution to choose from.

What is the order of the 6 layer PCB?

1. Top Layer: used to arrange the main electronic components and signal lines.

2. Top Layer Insulation: used to isolate the top conductive layer and the inner layer.

3. Inner conductive Layer 1 (Inner Layer 1) is used to arrange connection lines or power lines.

4. Inner Layer Insulation 1: plays the role of isolation.

5. Inner conductive Layer 2: It can also be used to arrange signal circuit or power supply circuit.

6. Bottom Layer: Used to arrange the bottom electronic components, connect lines or provide ground.

How thick is a 6-layer PCB?

The thickness of a 6-layer PCB usually depends on the specific design requirements and application scenarios. In general, the thickness of the 6-layer PCB can be between 1.0mm and 2.4mm, of which the most common is 1.6mm. PCB of different thickness will have different requirements and characteristics in the circuit design and manufacturing process.

When choosing the thickness of the PCB, it is necessary to consider the stability of the board, thermal management, mechanical strength, and cost. For some special application scenarios, such as high-frequency circuits or special industrial fields, there may be other requirements.

6 layer PCB thickness standard

The thickness standard of a 6-layer PCB usually depends on the specific requirements of the customer as well as the standards of the application field. The common 6-layer PCB thickness standard is 1.6mm, and this standard thickness is widely accepted in many applications. 6 layer PCB thickness standards are:

1. Mechanical strength requirements: Some applications may require a thicker PCB to provide sufficient mechanical strength to prevent the board from bending or damaging during use.

2. Thermal management requirements: For applications that need to deal with higher power or temperature, thicker PCBS can provide better heat dissipation, help manage temperature and ensure stable operation of electronic components.

3. Size limitations: For portable devices or microelectronic devices, thinner PCBS may be preferred because they can reduce the overall size and improve the compactness of the device.

4 layer vs 6 layer PCB cost

The 4 layer vs 6 layer PCB cost difference usually depends on several factors:

1. Board size and thickness: In general, larger and thicker PCBS cost more because they require more material and a more complex manufacturing process.

2. Increased number of layers: Compared with 4-layer PCB, 6-layer PCB requires more layers and more complex stack structure, which will increase the production cost.

3. Material selection: The use of high performance materials or special materials may increase the cost of PCB.

4. Production process: Manufacturing 6-layer PCB requires more complex process and more production steps, so it may increase the cost.

5. Lead time: If a shorter lead time is required, it may be necessary to rush the production, which may lead to additional costs.

6. Market supply and demand: The supply and demand relationship in the PCB market will also affect the cost, and suppliers usually set prices according to market demand and competition.

Get What is a 6 layer PCB board?

Previous:没有了!

Next:没有了!

6 layer pcb Description

What is a 6 layer PCB board? Related Articles

What is a 6 layer PCB board? Random Article

6 layer pcb News

6 layer pcb Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles