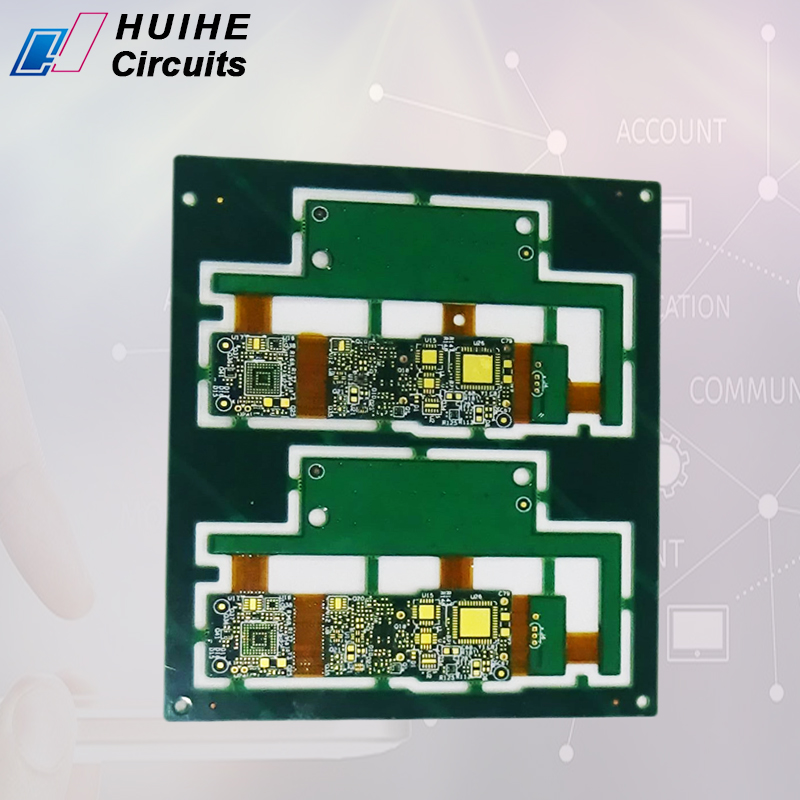

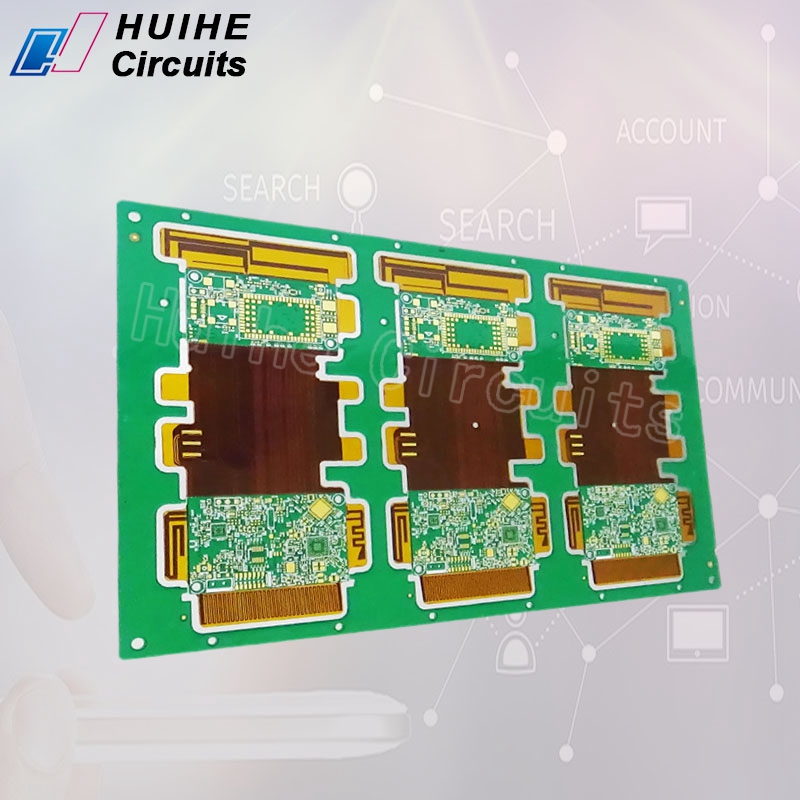

Rigid Flex PCB Board

Home < Rigid Flex PCB < Rigid Flex PCB Board

2022-11-19 18:31:40 Rigid Flex PCB 471 Viewed

SummaryRigid flex PCB boards are flexible circuit boards and rigid circuit boards, which are combined according to relevant process requirements after lamination and additional processes to form a circuit board with FPC characteristics and PCB characteristics. Initially, the basic design concept and manufa...

Rigid flex PCB boards are flexible circuit boards and rigid circuit boards, which are combined according to relevant process requirements after lamination and additional processes to form a circuit board with FPC characteristics and PCB characteristics. Initially, the basic design concept and manufacturing process of multilayer rigid flex PCB boards were developed from aerospace equipment, because reliable wiring must be carried out in a limited space. On the other hand, consumer electronics products, such as mobile phones and digital cameras, have always required high-density, low-cost wiring technology, so new design concepts and rigid flex PCB board manufacturing processes have emerged.

Multilayer rigid flex PCB boards are basically a combination of rigid boards and flexible boards. However, for circuit board manufacturers to successfully combine the two, they need to have a good level of both rigid flex PCB board manufacturing processes. Therefore, before designing such a rigid flex PCB board, it is necessary to clearly understand the capabilities and limitations of the PCB manufacturer.

Multi-layer Rigid Flex PCB Board Materials

Rigid flex PCB Board Materials | Traditional Materials | High-performance Materials |

FCCL | Traditional polyimide film | New polyimide film |

Copper Clad Laminate (Double Sided) | Polyimide substrate, acrylic adhesive (epoxy adhesive) | Adhesive-free polyimide-based laminates (cast or laminated) |

| Cover film | Traditional polyimide coated acrylic or epoxy adhesive | New Polyimide Coated Hot Melt Polyimide Adhesive |

| Adhesive sheet | Acrylic resin film, epoxy resin film, polyimide film coated with acrylic adhesive on both sides | New polyimide film coated with hot-melt polyimide resin on both sides |

CCL | Glass-Epoxy | Glass-BT resin board, Glass-polyimide resin board |

The above table lists several materials necessary for making rigid flex PCB boards. It should be pointed out that with the advancement of technology, the performance of these rigid flex PCB board materials has been significantly improved.

The material of the rigid flex PCB board must have high heat resistance and good dimensional stability during the heating process. Thick polyimide films (greater than 50um) are recommended for high-reliability fields (such as military industry, aerospace, etc.), because the substrate of rigid flex PCB boards needs to have good stability and durability during processing; while in the field of consumer electronics based on the development trend of light, thin and small, thinner dielectric (less than 50um) materials are generally used.

In glued copper clad laminates, cover films and adhesive sheets, the use of acrylic adhesives has better bonding force, but the heat resistance is slightly worse and the shrinkage rate is higher; the use of epoxy adhesive materials has better heat resistance, but the fixed time is longer and the binding force is slightly worse. The adhesiveless copper clad laminate base material manufactured by the casting or pressing industry usually has higher heat resistance and lower thermal expansion coefficient, and can reduce the thickness of the final product, so it is very advantageous in the production of rigid flex PCB boards. It can also significantly reduce drilling slag. However, this kind of rigid flex PCB board material must be processed at a temperature exceeding 300°C, so special equipment and process conditions are required.

Rigid flex PCB Board Manufacturing Process

Since the rigid flex PCB board has a variety of complex structural forms, the manufacturing process of the rigid flex PCB board is also different. Except for vias, other conductor patterns are formed using conventional etching processes. Therefore, there is no window covering film on the conductor cover in the flexible area, and the multi-layer flexible boards are bonded with adhesive sheets that have opened windows in the flexible area in advance, so that the flexible bending area will not be affected. The rigid outer cover layer (referring to the outermost rigid area), uses a double-sided rigid copper clad laminate.

The first step in the production of rigid flex PCB boards is to process the rigid outer cover layer, which requires the electroplating pattern of the laminated layer on the outer layer, and then through CNC milling, punching or laser methods, the part of the rigid layer located in the flexible area is hollowed out or at half the depth, the flexible board and the machined rigid outer cover are bonded by adhesive sheets. The adhesive sheet is pre-fenestrated in the flexible section.

During the lamination process of the rigid flex PCB board, if the rigid outer layer adopts a hollow structure, a suitable pressure-fitting filler board should be prepared for the flexible part. A vacuum press can be used to obtain better lamination quality, and at the same time cooperate with some auxiliary conformal materials (PE film, etc.), so that the lamination process can provide uniform pressure on the entire board, so that the low-flow adhesive sheet can fully flow to fill the gap, especially for complex structures. Proper baking should be done as needed to remove water before gluing or laminating.

The laminated rigid flex PCB board can use a through-hole treatment process similar to that of the multi-layer rigid board, the difference is that the desmear is removed. The method of desmearing depends on the material used. Like the hard board, the holes are drilled after fully baked, and then the plasma etching process is used to remove the resin residue in the hole wall. Before the plasma treatment, it also needs to be baked to remove water vapor. It is generally recommended that the degree of etchback should not exceed 13um, and the through-hole electroplating process of conventional rigid boards can be used, but the specific process parameters of electroplating should be determined according to the reliability test data of through-holes.

The next process is similar to the multi-layer rigid PCB board. The outer layer etching, cover film (solder mask), surface treatment, etc. can all use similar processes. After removing the part corresponding to the flexible area of the filling board or the depth-controlling rigid outer cover layer, it can be formed into a rigid flex PCB board.

Design Elements of Rigid Flex PCB Board

Rigid flex PCB boards have been widely used in electronic products. Rigid flex PCB boards involve more material differences, so all technical challenges mainly come from the selection of material combinations. For example, in a multiple lamination process, the CTE difference in each direction of each layer of material should be carefully considered and used together with a reinforcement plate so that high-precision alignment lamination can be achieved for deformation compensation.

At the same time, the structural design of rigid flex PCB boards is also a hot spot in its development. Generally speaking, there may be many design options for rigid flex PCB boards with equivalent functions. The actual design should start from a comprehensive consideration, including the reliability of the rigid flex PCB board product, occupied space, weight and assembly complexity. Additionally, for an optimal design with minimal procurement procedures, the rigid flex PCB board manufacturer's manufacturing capabilities and material factors should be considered. For example, common 3-layer to 8-layer rigid flex PCB boards can utilize CCL copper-clad laminates with or without adhesion. Similarly, the covering layer of the flexible area in the rigid flex PCB board has a different structure.

Another research and development trend of rigid flex PCB boards lies in the manufacture of component-embedded PCBs. In most cases, it is required to perform embedding of resistors and capacitors in rigid regions without compromising the performance of flexible regions. For the second time, this application places stringent demands on the material. In addition, flexible PCBs can work normally on CSP chip-scale packaging technology, while the component-embedded PCB structure poses challenges and requirements for packaging technology.

The Development Trend of Rigid Flex PCB Board

Rigid flex PCB boards have both the stability of rigid boards and the three-dimensional assembly of flexible boards, and their development prospects are very promising. In 2019, the global market size of rigid flex PCB board was about 1.66 billion US dollars, accounting for only about 2.8% of the overall circuit boards; but including smartphones, wireless headsets, drones, cars, AR/VR devices, etc. The highest product, and in the case of more and more follow-up applications, the rigid flex PCB board is still the product with the most growth momentum in 2020. It is estimated that the global market value of rigid-flex boards will reach nearly 2.3 billion US dollars in 2022, accounting for about 3.3% of the global circuit board output value.

Mobile device applications are the largest rigid flex PCB board market in 2019, accounting for about 43% of the overall rigid flex PCB board market, including smartphone camera lenses, screen signal connections, battery modules and other applications for rigid flex PCB boards. Substantially improved. Especially in the application of smartphone camera lenses, since multi-lens mobile phones have become the design trend of various mobile phone brands, whether it is the increase in the demand for rigid flex PCB boards or the increase in the average unit price, it will increase the market share of mobile device applications. proportion.

The development of rigid flex PCB boards for mobile phone lenses is mainly due to the lightweight, thin, and high-density requirements of mobile phone lenses, which need to be applied to rigid flex PCB boards. In addition, considering many factors such as placement position, direction, signal interference, heat dissipation, and specification settings, and some lenses adopt a periscope structure design due to optical zoom requirements, mobile phone lenses can meet increasingly stringent space constraints, there are many different types from the appearance, and the technical requirements for the rigid flex PCB board are more stringent, and its application range is wider.

Rigid Flex PCB Description

rigid flex pcb manufacturers, rigid flex pcb manufacturing process, rigid flex pcb board, 2 layer rigid flex pcb, 4 layer rigid flex pcb, 6 layer rigid flex pcb

What is a rigid flex PCB?

The birth and development of FPC and PCB gave birth to the new product of rigid flex PCB. Because the rigid flex PCB is a combination of FPC and PCB, the production of the rigid flex PCB should have both FPC production equipment and PCB production equipment.

Rigid flex PCB supplier

Huihe PCB is a rigid flex PCB manufacturer, providing quick turn rigid flex PCB, rigid flex PCB board, rigid flex PCB fabrication, rigid flex PCB assembly, rigid flex PCB prototype, rigid flex PCB design, rigid flex PCB quote and other services

Rigid Flex PCB Board Related Articles

Rigid Flex PCB Article

Rigid Flex PCB Manufacturers in China

Rigid Flex PCB Manufacturers in ChinaRigid Flex PCB News

Rigid Flex PCB Board

Rigid Flex PCB BoardRigid Flex PCB Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles