China PCBA Prototyping

Home < PCBA < China PCBA Prototyping

2022-12-13 14:46:15 PCBA 422 Viewed

SummaryPCBA Prototyping Process Products in the electronics industry are developing in a series of directions such as miniaturization, precision, thinness of the fuselage, and fan heat problems. The requirements for the assembly density of PCBA prototyping are getting higher and higher. Of course, the solde...

PCBA Prototyping Process

Products in the electronics industry are developing in a series of directions such as miniaturization, precision, thinness of the fuselage, and fan heat problems. The requirements for the assembly density of PCBA prototyping are getting higher and higher. Of course, the solder joints on the corresponding circuit boards are also getting higher and higher. The smaller it is, the higher the requirement for subsequent stability.

The PCBA prototyping not only needs to ensure the integrity of the patch, but also pay attention to whether the solder joints on the patch are complete, because if the solder joints are incomplete, there will be a series of problems such as solder joint failure and so on. Let me introduce to you. Let’s take a look at the specific operation process of the PCBA prototyping:

1. Customer order

Customers place orders with PCBA prototyping manufacturers and put forward specific requirements according to actual needs. The PCBA prototyping factory will evaluate its ability to see if it can complete the order. If the PCBA prototyping manufacturer determines that he can complete the order within a certain period of time, the two parties will negotiate to determine the details of each production.

2. Production documents provided by customers

After the customer decides to place an order, the PCBA prototyping factory will provide a series of documents and lists such as PCB electronic files, coordinate files, and BOM lists required for production.

3. Raw material procurement

The PCBA prototyping factory purchases relevant raw materials from designated suppliers according to the documents provided by customers.

4. Incoming material inspection

Before the PCBA prototyping, the PCBA prototyping factory needs to go through strict quality inspection for all raw materials used. It can be put into production after passing the test.

5. PCBA production

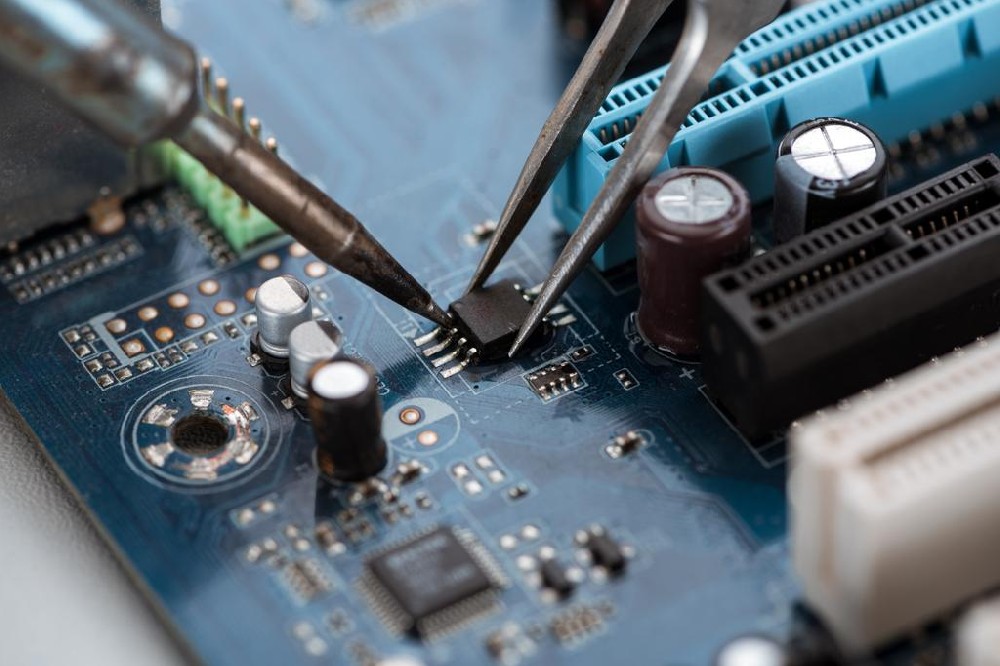

When conducting PCBA prototyping, in order to ensure production quality, PCBA prototyping manufacturers need to strictly control the furnace temperature, whether it is SMT production or welding production.

6. PCBA test

The PCBA prototyping factory also needs to undergo rigorous testing, and only PCB boards that pass the test can be delivered to customers.

7. Aftermarket packaging

After the PCBA prototyping is completed, the product needs to be packaged and then delivered to the customer to complete the entire prototype process.

Production Time of PCBA Prototyping

In order to effectively reduce the time for PCBA prototyping, PCBA prototyping manufacturers will carefully read the PCBA prototyping documents and contracts, determine the requirements of the entire prototype, and then prepare the required materials and arrange personnel in advance. If two shifts are required, arrange personnel attendance and shifts to ensure that all preparations except technical ones are completed.

PCBA prototyping scheme planning should be more standardized. For example, how many cooling holes should be reserved on the circuit board, such as where is the mark position of silk screen printing? It may just be a parameter written in the design, but it can effectively reduce the PCBA prototyping time.

It is also important to control the number of PCBA prototyping. If you plan too many quantities at the beginning, it will increase the cost, but try to have as many quantities as possible during PCBA prototyping, because the board may be burned during performance testing.

The above points are ways to shorten the PCBA prototyping time. In addition, the efficiency of PCBA prototyping is also related to factors such as technical experience. Therefore, as a PCBA prototyping processing enterprise, it should be improved technically.

The Functions of AOI in PCBA Prototyping

Quality inspection in PCBA prototyping is the key link to ensure quality. Only by strictly implementing quality inspection procedures can the quality of electronic processing products meet the needs of customers. AOI occupies a vital position in the production process of PCBA prototyping processing, and plays a great role in quality assurance.

Various PCB and PCBA prototyping manufacturers use AOI testing equipment. During automatic detection, the machine automatically scans the PCB through the camera, collects images, compares the tested solder joints with the qualified parameters in the database, and after image processing, checks out the defects on the PCB, and displays/labels the defects through the display or automatic signs out for repair by the maintenance crew.

AOI uses high-speed and high-precision visual processing technology to automatically detect various placement errors and soldering defects on the PCB. PCBA prototyping boards can range from fine-pitch high-density boards to low-density large-size boards, and can provide online inspection solutions to improve production efficiency and soldering quality.

The AOI system has technical advantages unmatched by other inspection schemes and traditional inspection methods, and has been widely used in PCBA prototyping testing. Its high-speed, high-efficiency and high-precision functional characteristics are favored by industry users.

1. The PCBA test system checks and corrects PCB defects, and the cost of doing it during process monitoring is much lower than that of doing it after final testing and inspection.

2. Can detect repetitive errors as early as possible, such as PCBA prototyping placement displacement or incorrect tray installation, etc.

3. The combination of statistical analysis function of PCBA prototyping detection technology and SPC process management technology provides a powerful weapon for the timely improvement of SMT production process, and the yield rate of PCBA prototyping assembly has been significantly improved. With the continuous expansion of the scale of modern manufacturing industry, the control of production is becoming more and more important, and the demand for SPC data is also increasing.

4. It can adapt to the detection requirements of PCBA prototyping assembly density. With the substantial increase in the assembly density of electronic products, some traditional testing technologies, such as ICT, can no longer meet the development requirements of SMT technology, while PCBA testing technology will not be affected by these factors.

5. The test program of PCBA prototyping testing equipment can be directly generated from Gerber data. Compared with ICT, since there is no need to make special fixtures, the test cost is also greatly reduced.

6. It can keep up with the production tempo of the SMT production line. According to the test results of PCBA prototyping inspection technology, it can currently achieve a speed of 0.1 seconds/frame, which can meet the requirements of online inspection.

7. The reliability of detection is high. Manual visual inspection always has its limitations, while PCBA prototyping test avoids the unfavorable factors in this respect and can maintain good accuracy and reliability.

8. Ensure the quality of PCBA prototyping products, reduce labor costs and improve labor productivity.

9. Non-contact measurement will not damage and scratch the PCB board.

10. Machine vision inspection technology can accomplish tasks that could not be completed in the past: for example, when dealing with some micro tube angles, the traditional method is often not competent, and the PCBA prototyping inspection system can realize the inspection.

PCBA Description

quick turn pcba, pcba assembly services, pcba services, pcba quotation, pcba quote, pcba assembly, pcba manufacturer usa, pcba manufacturing usa

what is pcba

pcba prototyping, pcba supplier, pcba production, pcba board manufacturers, pcba manufacturers, pcba manufacturing, pcba company, pcba factory, smt pcba, pcba boards, pcba design

what is pcba1

China PCBA Prototyping Related Articles

China PCBA Prototyping Random Article

Quick turn PCBA Supplier In China

Introduction to PCB Asupplier SMT C...

Quick Turn PCBA Assembly Services

Overview of the PCBA assembly For t...

What is PCBA Meaning & Means

Overview of pcba meaning PCBA is sh...

PCBA Factory

China PCBA factory SMT repair proce...

PCBA Manufacturing & PCBA Supplier in china

What is PCBA? PCB bare board throug...

PCBA China

PCBA China SMT Service point PCBA C...

How to Clean PCBA Boards Pollution?

Generally, the PCBA board of electr...

China PCBA Prototyping

PCBA Prototyping Process Products i...

PCBA Article

PCBA Manufacturing & PCBA Supplier in china

PCBA Manufacturing & PCBA Supplier in chinaPCBA News

PCBA China

PCBA ChinaPCBA Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles