What is PCBA Meaning & Means

Home < PCBA < What is PCBA Meaning & Means

2022-12-13 10:13:59 PCBA 463 Viewed

SummaryOverview of pcba meaning PCBA is short for Printed Circuit board + Assembly. pcba meaning refers to the whole production process of PCB Circuit board processing, SMT patch processing, DIP plug-in processing, Assembly, testing and packaging, that is to say, PCB bare board through SMT patch electronic...

What is PCBA Meaning Utube

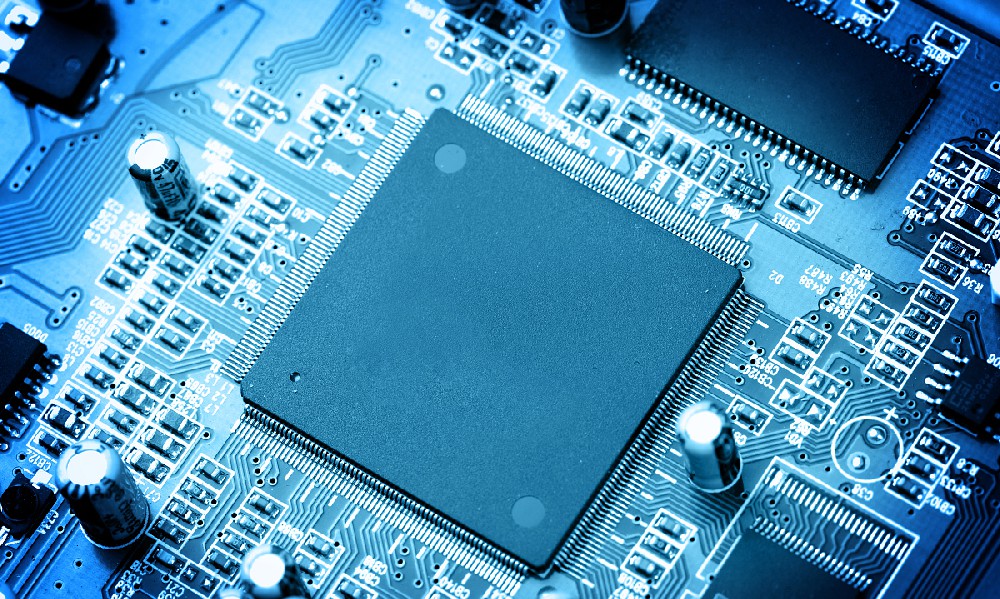

PCBA is short for Printed Circuit board + Assembly. PCBA meaning refers to the whole production process of PCB Circuit board processing, SMT patch processing, DIP plug-in processing, Assembly, testing and packaging, that is to say, PCB bare board through SMT patch electronic components, through the whole process of DIP plug-in.

The PCBA meaning in electronics manufacturing process is based on the PCB design document of the designer, and the bare PCB board is made by cutting, drilling, exposure development, etching, copper deposition, electroplating, surface treatment and other processes of the CCL, and then the electronic components are welded to the bare PCB board to form a PCBA board with a complete hardware structure. It is necessary to input the program into the PCBA board to enable it to control the on-off of the circuit and realize the design function of the product.

Waht is Aging pcba means

Aging PCBA meaning test is a process to simulate various factors involved in the actual use conditions of products to carry out the corresponding condition enhancement experiment. Aging PCBA means experiment mainly focuses on plastic materials. Common aging PCBA means tests mainly include light aging, wet heat aging and hot air aging. The product is frequently exposed to the sun when it is used outdoors. Of course, the intensity of the experiment is considerably greater than the actual outdoor light intensity.

Welding pcba meaning in electronics

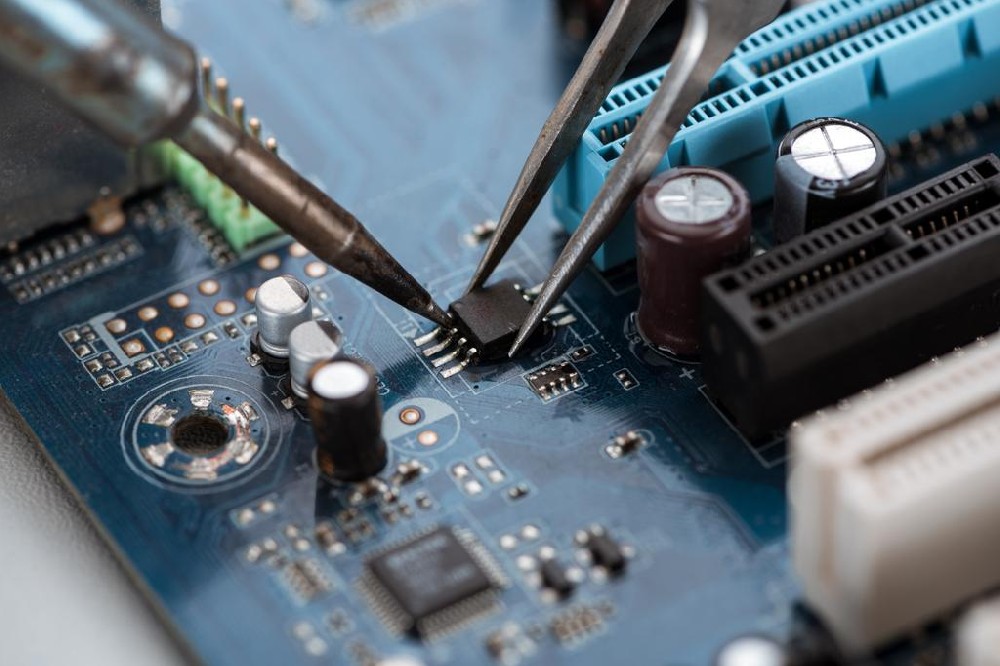

PCBA means the procurement of components, PCB production, SMT patch processing, DIP plug-in processing, PCBA testing and finished product assembly. PCBA processing has numerous processes. The following is the PCBA meaning in electronics of welding precautions.

1. The warehouse keeper of PCBA meaning in electronics shall wear anti-static gloves when issuing materials and conducting IQC inspection. The instrument shall be grounded reliably. The working table shall be paved with an anti-static rubber pad.

2. In the process of welding PCBA meaning in electronics, anti-static worktable shall be used, and components and semi-finished products shall be stored in anti-static containers. The welding equipment shall be reliably grounded, and the electric soldering iron shall be anti-static, which shall be tested before use.

3. When PCBA meaning in electronics is processed in the furnace, because the pins of plug-in components are scoured by the tin flow, some plug-in components will tilt after welding in the furnace, causing the component body to exceed the screen frame. Therefore, the repair welding personnel behind the tin furnace are required to correct it properly.

4. When welding PCBA meaning in electronics, pay attention not to having too much tin at the solder joint when welding the horn and battery, so as not to cause short circuit or falling off of surrounding components.

5. Welding PCBA meaning in electronics base plate shall be placed neatly, and bare plates shall not be stacked directly. If stacking is required, electrostatic bags shall be used for packaging.

Gas phase PCBA meaning Cleaning principle

The vapor phase PCBA meaning is a wave soldering cleaning method that heats the solvent through the equipment, vaporizes the solvent, and uses the solvent vapor to continuously evaporate and condense, so that the cleaned PCB workpieces can continually "sweat" and bring out pollutants. In order to improve the gas phase PCBA cleaning effect, it is normally used in combination with ultrasonic cleaning.

The gas phase PCBA meaning principle is that the bottom of the equipment is a heating immersion device and an ultrasonic cleaning tank, and several round cold meter tubes are installed around the tank wall above the PCBA meaning, where a condensation temperature zone ring is formed. When the solvent is heated to the gasification temperature, it begins to evaporate, and also evaporates to the workpiece to be cleaned. When the solvent vapor rises to the annular condenser, the solvent vapor condenses and falls on the workpiece to be cleaned.

Gas phase PCBA means cleaning process

The following is an overview of the gas phase PCBA meaning cleaning process:

1. First soak the workpiece in the heated cleaning solvent to formalize the pollutants.

2. Ultrasonic cleaning, so that the workpiece surface pollutants free down.

3. Gas phase cleaning, gas phase cleaning is equivalent to Ge gas, solvent degassing is highly pure, the use of solvent degassing continuously makes the cleaning workpiece "sweat" and brings out the pollutants of PCBA meaning cleaning out.

4. Rinse with cleaner cleaning solvent.

5. Finally spray with a clean cleaning solvent.

PCBA Description

quick turn pcba, pcba assembly services, pcba services, pcba quotation, pcba quote, pcba assembly, pcba manufacturer usa, pcba manufacturing usa

what is pcba

pcba prototyping, pcba supplier, pcba production, pcba board manufacturers, pcba manufacturers, pcba manufacturing, pcba company, pcba factory, smt pcba, pcba boards, pcba design

what is pcba1

What is PCBA Meaning & Means Related Articles

What is PCBA Meaning & Means Random Article

What is PCBA Meaning & Means

Overview of pcba meaning PCBA is sh...

Quick Turn PCBA Assembly Services

Overview of the PCBA assembly For t...

PCBA China

PCBA China SMT Service point PCBA C...

How to Clean PCBA Boards Pollution?

Generally, the PCBA board of electr...

China PCBA Prototyping

PCBA Prototyping Process Products i...

PCBA Manufacturing & PCBA Supplier in china

What is PCBA? PCB bare board throug...

Quick turn PCBA Supplier In China

Introduction to PCB Asupplier SMT C...

PCBA Factory

China PCBA factory SMT repair proce...

PCBA Article

PCBA Manufacturing & PCBA Supplier in china

PCBA Manufacturing & PCBA Supplier in chinaPCBA News

PCBA China

PCBA ChinaPCBA Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles