China PCB Board Manufacturing

Home < PCB Board < China PCB Board Manufacturing

2023-01-03 15:21:25 PCB Board 342 Viewed

SummaryPCB board is one of the important parts of the electronics industry. The PCB board is composed of an insulating base plate, connecting wires and pads for assembling and welding electronic components, and has the dual functions of a conductive line and an insulating base plate. As small as electronic...

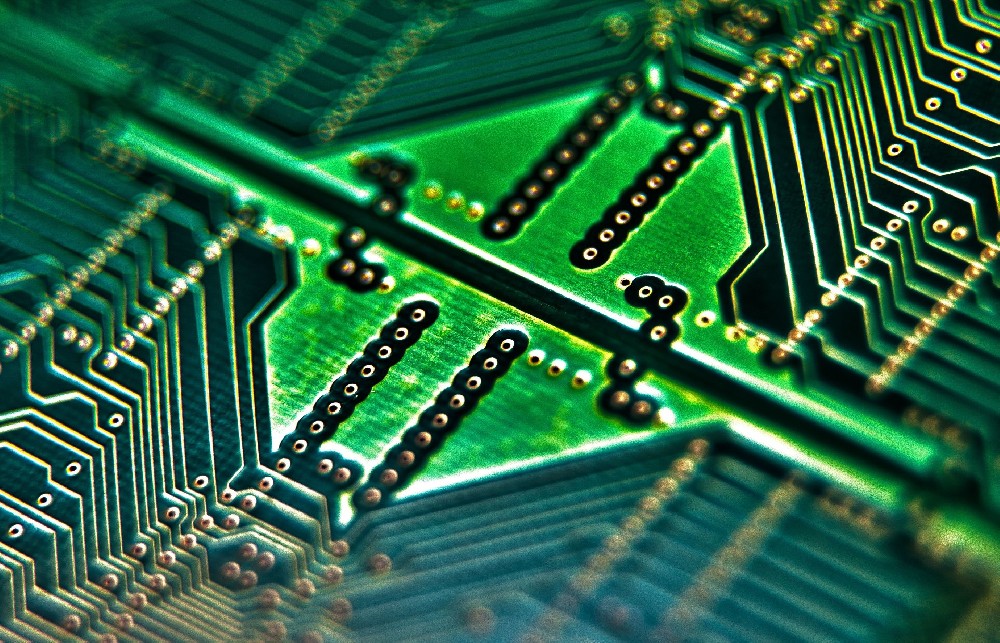

PCB board is one of the important parts of the electronics industry. The PCB board is composed of an insulating base plate, connecting wires and pads for assembling and welding electronic components, and has the dual functions of a conductive line and an insulating base plate. As small as electronic watches and calculators, as large as computers, communication electronic equipment, and military weapon systems, as long as there are electronic components such as integrated circuits, PCB boards must be used for the electrical interconnection between various components.

The PCB board can replace the complex wiring and realize the electrical connection between the components in the circuit, which not only simplifies the assembly and welding work of electronic products, but also reduces the wiring workload in the traditional way, greatly reducing the labor intensity of workers; the PCB board shrinks. The volume of the whole machine reduces the product cost and improves the quality and reliability of electronic equipment.

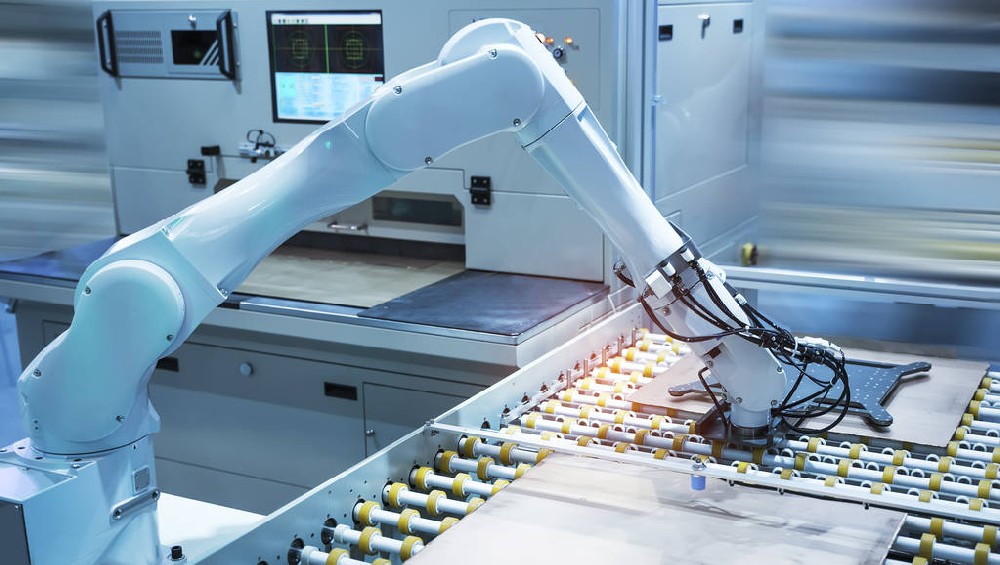

The PCB board has good product consistency, and it can adopt a standardized design, which is conducive to the realization of mechanization and automation in the production process. At the same time, the entire assembled and debugged PCB board can be used as an independent spare p5art, which is convenient for the exchange and maintenance of the whole machine. At present, PCB boards have been widely used in the production and manufacture of electronic products.

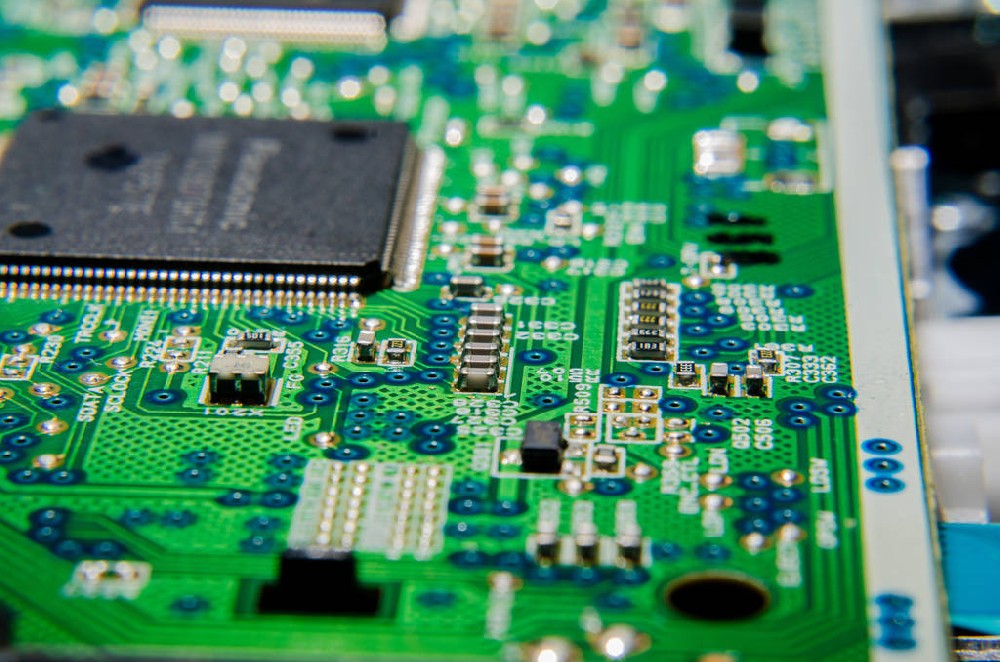

The earliest use of PCB boards was paper-based copper-clad printed boards. Since the appearance of semiconductor transistors in the 1950s, the demand for PCB boards has risen dramatically. Especially with the rapid development and wide application of integrated circuits, the volume of electronic equipment is getting smaller and smaller, and the density and difficulty of circuit wiring are getting higher and higher, which requires the PCB board to be constantly updated. At present, the variety of PCB boards has developed from single-sided PCB boards to double-sided PCB boards, multi-layer PCB boards and flexible PCB boards; the structure and quality have also developed to ultra-high density, miniaturization and high reliability; PCB boards are new Advanced design methods, design supplies, board-making materials, and board-making processes are emerging. In recent years, various computer-aided design (CAD) PCB board application software has been popularized and promoted in the industry. In professional PCB board manufacturers, mechanized and automated production has completely replaced manual operations.

Features of PCB Board

The reason why PCB boards can be used more and more widely is because it has many unique advantages, which are roughly as follows:

High density possible

Over the years, the high density of PCB boards has been able to develop correspondingly with the improvement of integrated circuit integration and the advancement of mounting technology.

High reliability

Through a series of technical means such as inspection, testing and aging test, the PCB board can be guaranteed to work reliably for a long time (generally 20 years).

Designability

The requirements for various properties (electrical, physical, chemical, mechanical, etc.) of PCB boards can be achieved through standardization and standardization of design. In this way, the design time is short and the efficiency is high.

Productivity

The PCB board adopts modern management, which can realize standardization, scale (quantity) and automatic production, so as to ensure the consistency of product quality.

Testability

A relatively complete test method and test standard has been established, and various test equipment and instruments can be used to detect and identify the qualification and service life of PCB board products.

Assemblability

PCB board products are not only convenient for standardized assembly of various components, but also can be automated and large-scale mass production. In addition, the overall assembly of the PCB board and various other components can also form larger components, systems, and even the whole machine.

Maintainability

Since PCB board products and components assembled as a whole are designed and produced in a standardized manner, these components are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly, and the work of the system can be quickly restored.

The PCB board also has some other advantages, such as making the system miniaturized, lightweight, and high-speed signal transmission.

Classification of PCB Boards

(1) According to the method of making the conductive pattern of the PCB board, it is divided into a subtractive method PCB board and an additive method PCB board.

The PCB subtractive process is a method of selectively removing part of the copper foil on the surface of the copper-clad laminate to obtain a conductive pattern. The subtractive method is the main method of PCB board manufacturing today, and its biggest advantage is that the process is mature, stable and reliable.

(2) According to the nature of the substrate, it can be divided into organic PCB board and inorganic PCB board.

Organic PCB boards are mainly composed of resins, reinforcing materials and copper foil, and the resin materials can be divided into phenolic resins, epoxy resins, polyimides; inorganic PCB boards are mainly made of ceramics and aluminum, etc. It is composed of thick and thin film circuits, which are widely used in high-frequency electronic instruments. At present, the common PCB boards are all organic PCB boards.

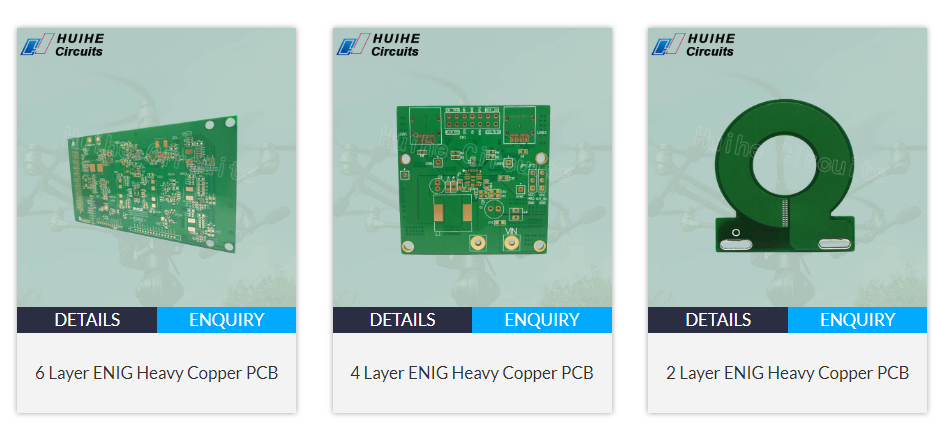

(3) According to the conductive structure of the PCB board, it can be divided into single-sided PCB board, double-sided PCB board, and multi-layer PCB board. This is the most common classification method.

PCB Board Software

Commonly used PCB board design software providers include Altium, Cadence, Mentor, etc. Among them, Protel 99 SE, Protel DXP, Altium Designer, etc. launched by Altium Company are widely used in my country. At present, Altium Designer, PADS has a new version released every year. For PCB board design software, learn to use one, and the rest will be easier to learn, because the functions of such software are very close.

Get China PCB Board Manufacturing

Previous:Military PCB manufacturers

PCB Board Description

pcb board assembly, pcb board fabrication, pcb board company, pcb circuit boards, pcb board diy, pcb board maker, pcb boards, pcb board manufacturer, custom PCB board, prototype PCB board, PCB board assembly manufacturing

What is a PCB board?

PCB board, also known as printed circuit board, PCB board is composed of insulating bottom plate, connecting wire and welding plate assembly of electronic components, is an important electronic component. At present, PCB board has been widely used in electronic products

How to design PCB board?

Before the PCB board design, it is necessary to prepare the logic package of schematic SCH and the packaging library of PCB board. First do PCB board packaging library, PCB board packaging library requirements are higher, it directly affects the installation of PCB board.

China PCB Board Manufacturing Related Articles

China PCB Board Manufacturing Random Article

China PCB boards

PCB boards material The flammabilit...

Flexible Printed Circuit Boards Prototype

Flexible Circuits Boards Prototype ...

4 Layer Multi Layer PCB

PCB manufacturers are developing va...

China flex circuit assembly

Flex circuit assembly process 1. Pr...

Double Sided PCB

Double sided PCB is a printed circu...

Multilayer Flexible PCB boards

single layer flexible pcb boards Th...

China high tg pcb manufacture

High Tg PCB manufacturer High tg PC...

Multilayer PCB Assembly

What is Multilayer PCB Assembly One...

PCB Board Article

Heavy Copper PCB USA

Heavy Copper PCB USAPCB Board News

Automotive PCB Applications

Automotive PCB ApplicationsPCB Board Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles