China PCB boards

Home < PCB Board < China PCB boards

2022-12-09 16:37:09 PCB Board 398 Viewed

SummaryPCB boards material The flammability of PCB boards material, also known as flame retardant and flammability, is the ability to evaluate the material's combustion resistance. HB plate has low flame retardant and is mostly used for single panel; vO board has high flame retardant and...

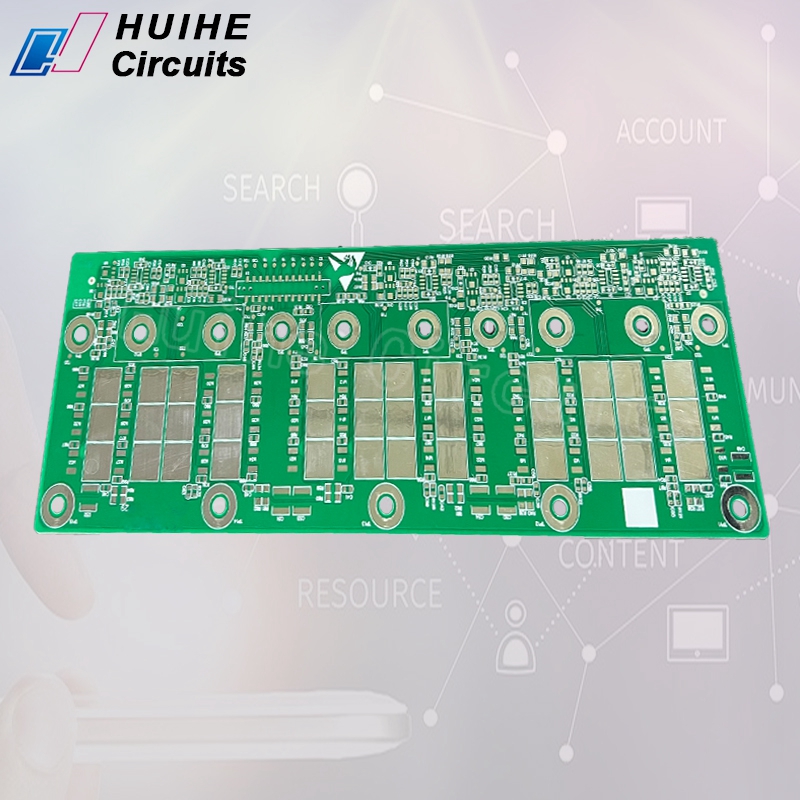

China PCB boards material

The flammability of China PCB boards material, also known as flame retardant and flammability, is the ability to evaluate the material's combustion resistance. HB plate has low flame retardant and is mostly used for single panel; vO board has high flame retardant and is used for double panel and multi-layer PCB boards.

China PCB boards must be fire resistant and can only be softened at a certain temperature, which is called glass transition temperature (Tg point). This value is related to the size stability of China PCB boards. China PCB board material can be divided into 94HB-94VO-22F-CEM-1-CEM-3-FR-4 according to grade level from low to peak. The introduction is as follows :

1. 94HB : ordinary cardboard, no fire (the lowest grade material, die punching, can not be a power board)

2. 94V0 : flame retardant cardboard (die punching)

3. 22F : single side half glass fiber board (die punching)

4. CEM-1 : single glass fiber board (must be computer drilling, can not die punching)

5. Cim-3 : double-sided half-glass fiber board

6. FR-4 : Double-sided fiberglass board

The Tg value of China PCB Boards

The Tg value of China PCB boards is the highest temperature (℃) at which the substrate maintains rigidity. That is to say, the ordinary China PCB boards substrate material not only produces softening, deformation, melting and other phenomena at elevated temperature, but also manifests in the decline of mechanical and electrical characteristics. Normally, China PCB boards with Tg≥170℃ are called high Tg PCB boards. The higher the Tg value of China PCB boards, the higher the heat resistance, moisture resistance, chemical resistance, stability resistance and other characteristics will be increased and improved.

With the rapid development of the electronic industry, especially the electronic products represented by computers are developing towards great function and strong multilayer, the higher heat resistance of China PCB boards is needed as an essential guarantee. With the emergence and development of high density installation technology represented by SMT and CMT, China PCB boards are increasingly dependent on the support of high heat resistance of substrate in terms of narrow aperture, fine wiring and thin shape.

China PCB boards printing reinforced material classification

1. Phenolic paper substrate of China PCB boards printing

Because China PCB boards are composed of pulp and wood pulp, it is occasionally also called cardboard, V0 board, flame retardant board and 94HB, etc. Its main material is wood pulp fiber paper, which is pressurized by phenolic resin and synthesized by China PCB board printing. This paper substrate is characterized by no fire, can be punched processing, low cost, economical price, relatively modest density.

2. Laminated substrates for China PCB boards printing

The composite substrate of China PCB board printing is made of wood pulp fibre paper or cotton pulp fibre paper as the reinforcement material, supplemented by glass fibre cloth as the surface reinforcement material, both materials are made of flame retardant epoxy resin, of which CEM-1, CEM-3 is the most common composite China PCB boards.

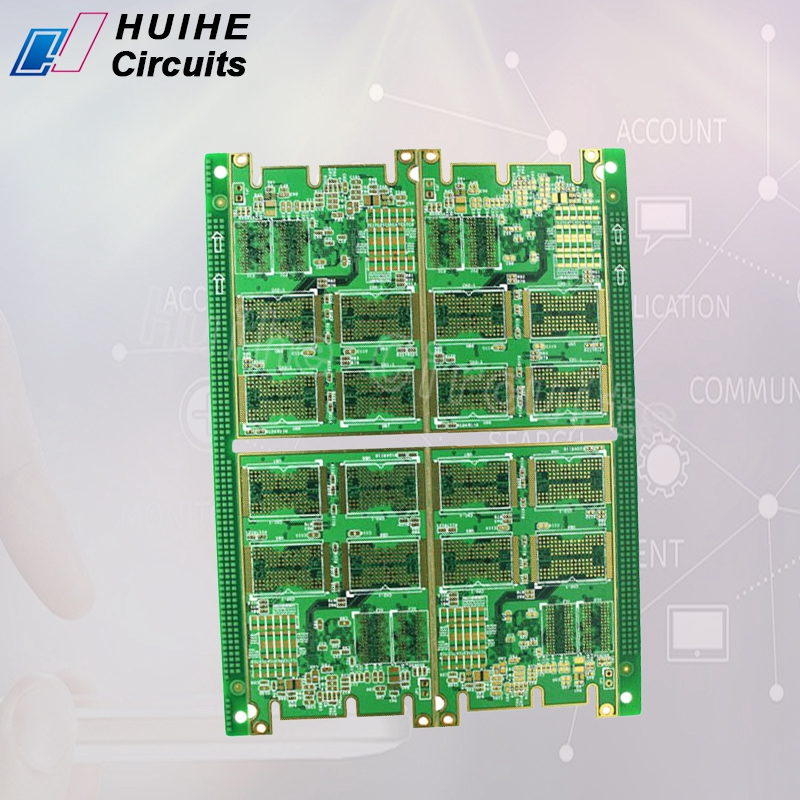

3. China PCB boards printing glass fiber substrates

The glass fiber substrate of China PCB board printing is made of epoxy resin as binder and glass fiber cloth as reinforcing material. This kind of China PCB board has a high operating temperature. It has slight impact on the environment and is suitable for various power supply boards, multi-layer China PCB board printing, computer peripheral equipment, communication equipment and other applications.

4. Alternative substrates of China PCB boards printing

In addition to the three commonly seen above, there are also metal substrates and laminated multilaminates (BUMs).

China PCB boards repair techniques

Most China PCB boards do not have official schematic diagram, and chips with programs are used more and more, proved by a lot of practice. The following is an overview of China PCB board repair techniques.

1. China PCB boards appearance inspection method

2. China PCB boards pass killing method

3. Comparison of China PCB boards

4. Status method of China PCB boards

5. Replacement method of China PCB boards

6. China PCB boards of the circuit method

7. Principle analysis of China PCB boards

The above China PCB boards repair skills and methods require engineers to invest huge patience and careful work attitude in order to do a fine job.

Law of industrial China PCB boards repair

Industrial China PCB boards need frequent maintenance, so what are the rules for industrial China PCB boards repair?

1. China PCB boards repaired to understand the vulnerable parts on the circuit board

2. Damage characteristics and detection of common components of industrial China PCB boards

3. Industrial China PCB boards repaired to have a block diagram

You can verify different China PCB boards products according to the above method, such as switching power supply, which is constantly inseparable from oscillating circuit, switching tube and switching transformer. During inspection, check whether the circuit is vibrating, whether the capacitor is damaged, and whether the triode and diode are damaged. In addition, maintenance should pay attention to the maintenance order to find the shortest path to solve the problem, to avoid the possibility of fault expansion.

Semiconductor potting China PCB boards trend

Semiconductor, as the cornerstone of the electronics industry, has been closely linked with the electronics industry, and most of the core units of electronic products are closely related to the semiconductor industry. The semiconductor industry is continually updated and expanding. At the same time, due to the Internet of Things, wireless communication, automotive electronics, artificial intelligence, consumer electronics and other fields of innovation, also help promote the development of semiconductor potting China PCB boards industry.

With the development of the consumer electronics market and the Internet of Things, the development of chip miniaturization, elevated speed and elevated reliability has put forward higher requirements for the temperature resistance and other electrical properties of packaging materials. Therefore, potting China PCB boards material has become one of the key materials for the development of the electronics industry.

PCB Board Description

pcb board assembly, pcb board fabrication, pcb board company, pcb circuit boards, pcb board diy, pcb board maker, pcb boards, pcb board manufacturer, custom PCB board, prototype PCB board, PCB board assembly manufacturing

What is a PCB board?

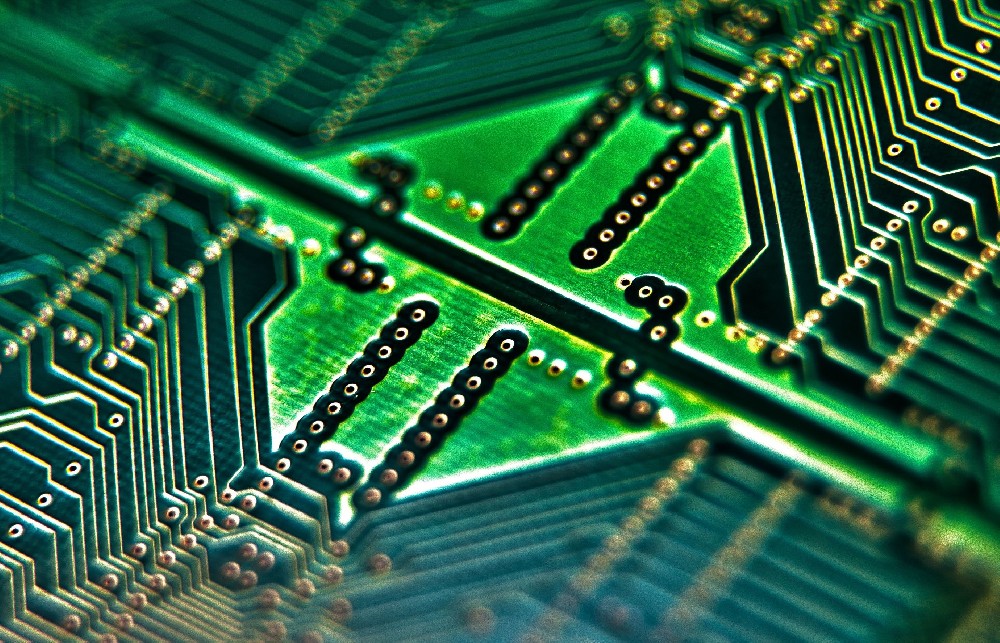

PCB board, also known as printed circuit board, PCB board is composed of insulating bottom plate, connecting wire and welding plate assembly of electronic components, is an important electronic component. At present, PCB board has been widely used in electronic products

How to design PCB board?

Before the PCB board design, it is necessary to prepare the logic package of schematic SCH and the packaging library of PCB board. First do PCB board packaging library, PCB board packaging library requirements are higher, it directly affects the installation of PCB board.

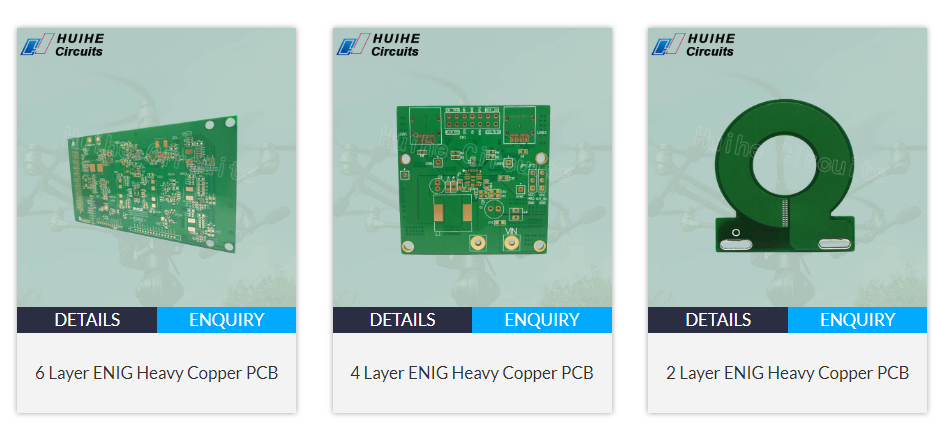

China PCB boards Related Articles

China PCB boards Random Article

6 Layer Multilayer Printed Circuit Board Fabrication

A 6-layer multilayer printed circui...

Multilayer PCB Assembly

What is Multilayer PCB Assembly One...

Multilayer Flexible PCB boards

single layer flexible pcb boards Th...

Aluminum PCB board contents

What is an aluminum PCB board? 1. A...

Flexible Printed Circuit Boards Prototype

Flexible Circuits Boards Prototype ...

Multi Layer PCB Manufacturing Process

What is Multi Layer PCB?A Multi Lay...

Double Sided PCB

Double sided PCB is a printed circu...

China PCB boards

PCB boards material The flammabilit...

PCB Board Article

Heavy Copper PCB USA

Heavy Copper PCB USAPCB Board News

Automotive PCB Applications

Automotive PCB ApplicationsPCB Board Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles