China Flexible PCB Fabrication Process

Home < Flexible PCB Fabrication < China Flexible PCB Fabrication Process

2022-10-28 13:50:29 Flexible PCB Fabrication 552 Viewed

SummaryFlexible PCB Fabrication provides what files?Flexible PCB Fabrication refers to the process that electronic engineers send flexible PCB manufacturers FPC boards to test the performance of electronic products after completing circuit design. Because it is a newly developed product, many functions are...

What Is Flexible PCB Fabrication ?

Flexible PCB Fabrication refers to the process that electronic engineers send flexible pcb manufacturers FPC boards to test the performance of electronic products after completing circuit design. Because it is a newly developed product, many functions are still not perfect, and numerous functions need to be debugged. Only after the debugging is qualified can the mass production be carried out. If the debugging is not qualified, the Prototype and debugging need to be modified again. However, the number of flexible pcb fabrication production is typically limited, normally between 10 and 50PCS. Of course, there are also requirements for more than this number, which is mainly the verification stage before the product design confirmation and test is completed by engineers. Then, what files should flexible pcb fabrication provide?

China Flexible PCB Fabrication Process

Flexible PCB Fabrication will be carried out before the mass production of flexible pcb. Mass production will be carried out only after the quality function of flexible pcb is OK. Flexible PCB Fabrication proofing can prove beneficial in nearly any situation where current or updated designs are involved. Under normal circumstances, german files or pcb files should be provided to the manufacturer, and some customers will also directly send CAD files. Secondly, the process requirements of Gerber file should be provided, including the specific requirements and parameters of board quantity, board thickness, surface treatment process, materials, etc., so that flexible pcb manufacturers can evaluate the process and make production materials according to the documents provided by customers. The content of the documents specifically includes the following information:

Materials: For Flexible PCB Fabrication materials, PI polyimide is the most widely used material.

Plate thickness: The finished product thickness of Flexible PCB needs to be marked. Some FPC also need to be attached with auxiliary materials, and the auxiliary materials thickness also needs to be marked.

Surface treatment: HASL, LF-HASL, ENIG, Imm Tin, OSP, Imm Gold Finger, the function is to prevent oxidation and soldering on tin.

Solder resistance color: there are numerous kinds of color, can also be selected according to the requirements, the general is yellow film.

Screen printing color: color of the font and border of the screen printing on the FPC board, Typically, white is selected.

Quantity: The quantity of FPC should be stated clearly.

Flexible PCB Fabrication requires two kinds of files? In the first case, the electronic engineer has designed circuit files. At this time, only Gerber files or PCB files of electronic circuits need to be provided to the factory. In addition to these, flexible pcb fabrication process requirements, such as materials, plate thickness and surface treatment, should also be provided. The second situation is that the electronic engineer has not designed the circuit properly and only has physical samples. In this case, the customer needs to provide the FPC material to flexible pcb manufacturers. Flexible PCB Manufacturers will copy board according to FPC board, copy Gerber file and process requirements, and then make flexible pcb fabrication according to the file. The above is the explanation that flexible pcb fabrication should provide documents to the factory, and the customer will decide according to his own actual situation.

Considerations in China Flexible PCB Fabrication

A large area of the field as much as possible not with tiny print, dot and other details on a board, even if the same color should be divided into two boards as much as possible, if it is not separated (such as the printing press color group number limit and other reasons), consider appropriate local pad.

Try to avoid large area solid multi-color overprinting.

The specification of the text should not be too narrow. Otherwise, when the pressure changes during the flexible pcb fabrication process, the printed text will show a large amount of deformation, which will make the text thin or blurred.

The width of individual thin lines should be greater than 0.2 mm.

In flexible pcb fabrication, the engraving angle of the ink hole on the ink transfer roller is usually 45°. Therefore, when printing with the ordinary type of ink transfer roller, the cable Angle of 45° should be avoided on the printed board to avoid more printed matter.

China Flexible PCB Fabrication Design

Avoid designing wide and tall bars and fields along the horizontal direction of the printing drum, which will cause machine vibration. It is ideal to use diagonal lines, curves, wave lines and other irregular curves.

Avoid designing large circular patterns on the pcb surface. If flexible pcb fabrication occurs during elastic stretching or compression, regular geometric patterns will become irregular and circular patterns will become ellipses.

Avoid the precise overprinting requirements of tight seams.

The color design of the manuscript should take into account the maximum number of colors the printing press can print.

In the use of ink color, should not be overprinted with two equal color blocks to avoid inaccurate overprinting and affecting the quality of printing. Can be used in a larger area of the field color block on the local overprint text or pattern patterns and overprint local color block.

Get China Flexible PCB Fabrication Process

Previous:没有了!

Next:没有了!

Flexible PCB Fabrication Description

flexible pcb fabrication, china flexible pcb fabrication, flexible pcb fabrication factory, flexible pcb fabrication process, flexible pcb fabrication supplier

Flexible PCB fabrication process

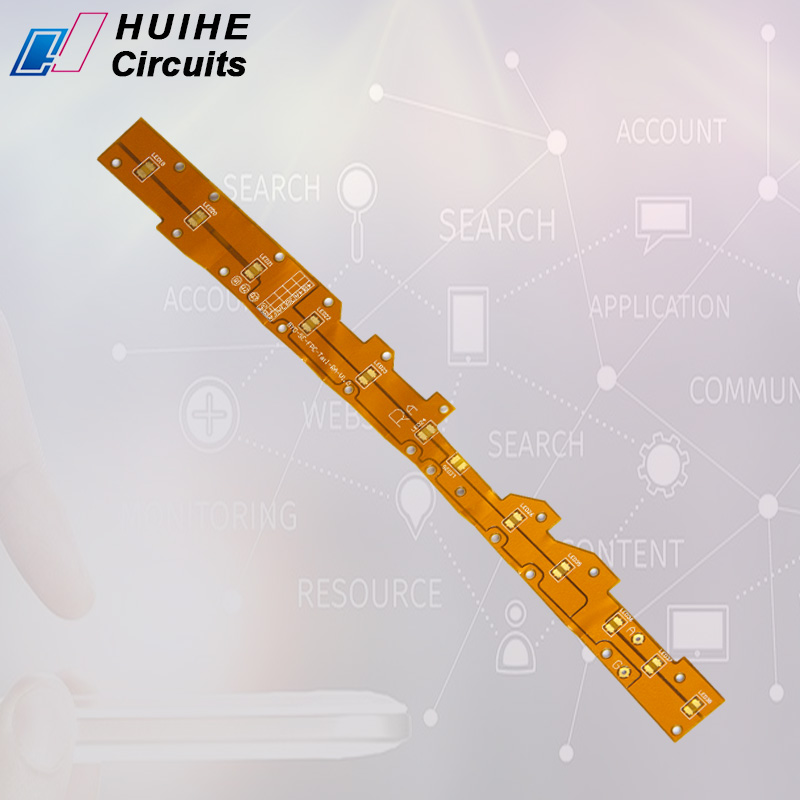

The biggest difference between flexible PCB fabrication and traditional rigid PCB fabrication is the "past-compression" process of covering film and reinforcing board shielding layer. In flexible PCB fabrication, covering film is used instead of solder choke. Some people refer to flexible PCB fabrication as "past-compression" for short. Very aptly reveals the characteristics of flexible PCB fabrication processing

Advantage of flexible PCB fabrication

The main advantages of flexible PCB fabrication are its flexibility and bending ability. Flexible PCB fabrication provides greater freedom of design. It is thin and light, which can greatly reduce weight and space and can be folded. Making flexible PCB fabrication suitable for small equipment

China Flexible PCB Fabrication Process Related Articles

China Flexible PCB Fabrication Process Random Article

Flexible PCB Fabrication Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles