PCB Prototype Contents

Home < PCB Prototype < PCB Prototype Contents

2022-10-28 18:07:19 PCB Prototype 550 Viewed

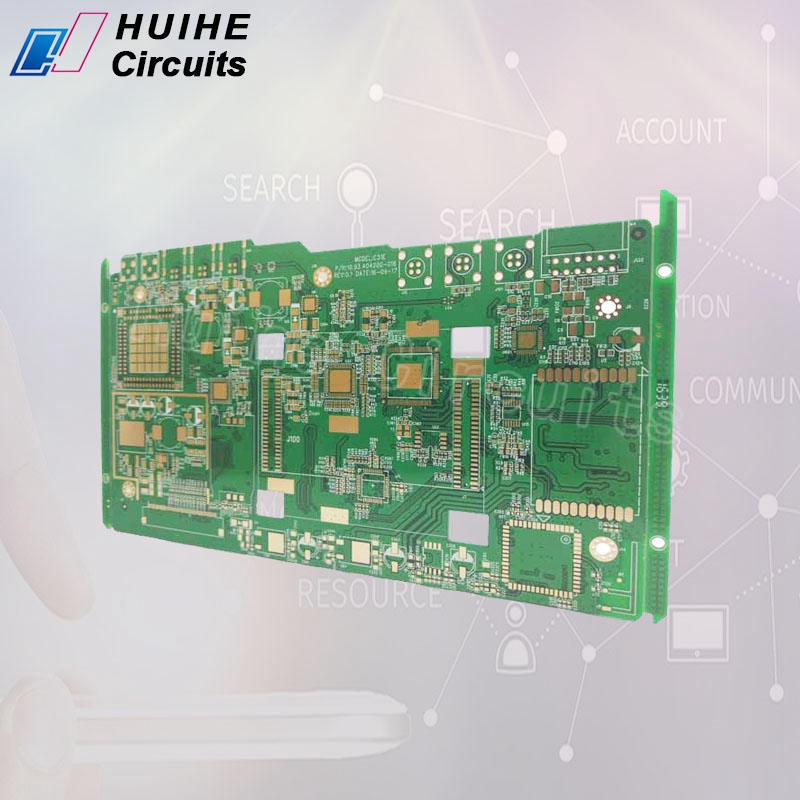

SummaryPreparation before PCB Prototype PCB Prototype refers to the trial production of printed circuit boards before mass production. There are simple and complex circuit boards.A simple PCB Prototype is easy, but if it is a complex PCB Prototype, you need to be careful. If something goes wrong, it's t...

Preparation before PCB Prototype

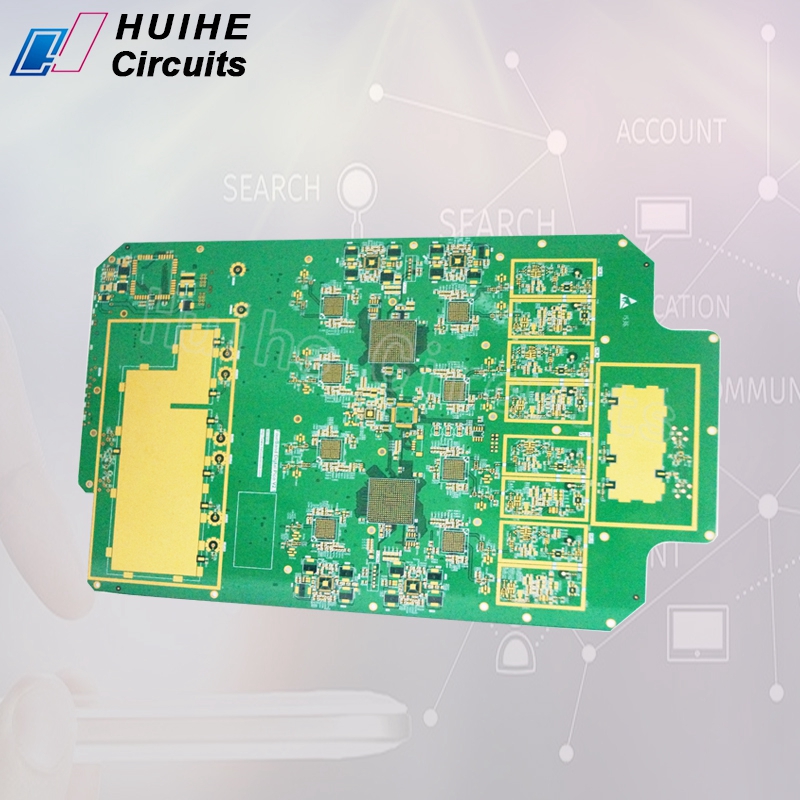

PCB Prototype refers to the trial production of printed circuit boards before mass production. There are simple and complex circuit boards.A simple pcb prototype is easy, but if it is a complex pcb prototype, you need to be careful. If something goes wrong, it's too late to find out when the PCB is ready, so be sure to do your homework before pcb prototype.

Physical frame production

The closed physical frame has a good standard effect on the layout of components after, we must pay attention to precision, and it is best to use the arc in the corner place, not only can avoid being scratched by sharp corners, but also can reduce the stress effect.

Introduce components and network to layout components

When drawing components and networks into the painted frame on pcb prototype, be sure to follow the instructions carefully, including the form of the component package and the component network issues. Because the control prompts, it is not easy to cause problems. In PCB Prototype, the layout of components and wiring has a great impact on the product life, stability, electromagnetic compatibility, is a special place to pay attention to. Roughly speaking, there should be the following principles: placement sequence, attention to heat dissipation.

PCB design and wiring and adjustment

When designing and wiring PCB, it is better to pay attention to the requirements of pcb prototype parameters, or to a reliable pcb prototype manufacturer, the defect rate will be greatly reduced; After PCB design and wiring is completed, it is necessary to make some adjustments to the text, individual components, wiring and copper application. This work should not be done too early, otherwise it will affect the speed and wiring, which is also for the convenience of production, debugging and maintenance.

Check the network

Sometimes, due to misoperation or negligence, the network relationship of pcb board drawn is different from the schematic diagram. At this time, it is necessary to check and verify, so after drawing should be checked first, and then carry out the follow-up work.

This is pcb prototype needs to do before the introduction of preparation work, I hope to help you.

PCB Prototype Precautions

PCB Prototype refers to the trial production before the batch production of printed circuit boards. It is mainly used for the pcb prototype before the electronic technicians confirm the circuit design and complete the experiment.

Here is a note on pcb prototype precautions:

Carefully check the PCB file to avoid data problems

Complete process audit and process configuration with manufacturer

Excellent control of production, quality and cost saving

Adequately communicate with the manufacturer to prevent accidents in advance

PCB Prototype Cycle:

Normally about seven days, it can be urgent; board proofing 3-4 days to ship; four-layer board proofing 6-7 days delivery;

according to the production capacity of each factory, mass production normally takes about 8-10 days.

PCB Prototype quote method:

Prototype quote calculation method: engineering cost + board cost * quantity + paving cost + paving cost + special process cost.

PCB Prototype way:

There are three types of pcb prototype: formal pcb manufacturers, professional sample companies and a few board copying companies. The purpose of formal pcb prototype manufacturers is to have an advantage on the premise of a large number of orders, while professional proofing companies only accept sample or tiny batch, professional and swift, suitable for modest amount of sample production, large orders can not bear.

In terms of quality assurance, formal pcb manufacturers must be better than professional pcb prototype companies. Professional pcb prototype companies are sold in a single blow. They collect money when sending samples. Formal pcb manufacturers commonly do fly needle testing, from materials to technology are meticulous, professional.

A few circuit board companies are also engaged in pcb prototype, after submitting materials to the customer and confirming the final scheme, quickly providing the customer with pcb prototype, functional prototype production and testing, to ensure the feasibility of the product.

PCB Prototype Production steps

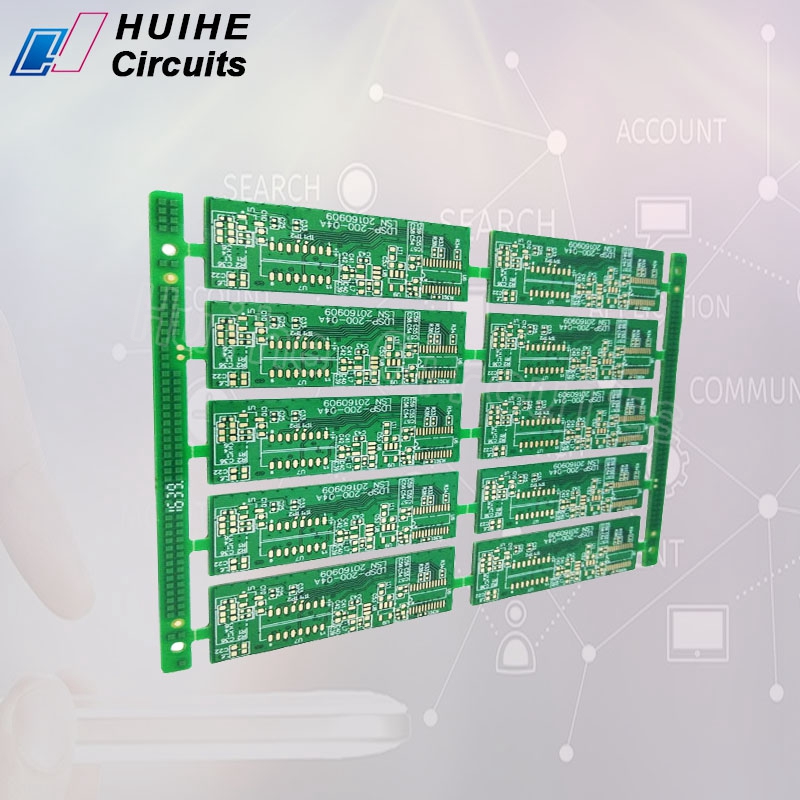

PCB Prototype means that before the batch production of circuit boards, a modest amount of pcb prototype board is produced in advance for functional debugging. After the function debugging is completed, the following batch production can be carried out. This way can avoid production risks and reduce losses caused by product errors. Let's take a look at the specific steps of the pcb prototype board!

Customers need to inform pcb manufacturers of sample size, process requirements, product quantity and other relevant data through drawing documents, and then professionals will provide quotation, urge orders and follow up the production situation.

According to customer's requirements, the relevant board, cutting board items conform to the requirements of production, the specific process: large sheet metal - cutting board to curium board according to the requirements of the MI - gong rounded corner/edge grinding to the board.

Drill holes according to pcb prototype drawings and drill holes in appropriate positions that meet the size requirements. The specific process is as follows: laminated plate pin → upper plate → drilling → lower plate → inspection/repair.

Copper sinking, use chemical method to deposit a thin layer of copper on the surface of the insulation hole, the specific process: coarse grinding → hanging plate → automatic copper sinking line → lower plate → dipping 1% dilute H2SO4→ thickened copper.

Graphics transfer, the production film on the graphics transfer to the board. Specific process: hemp plate → pressing film → static position → exposure → static position → impact → check.

Graphic electroplating, electroplating a layer of copper, gold, nickel or tin on the exposed copper skin or hole wall of the line graphics to meet the thickness requirements, the specific process: upper plate → oil removal → washing secondary → micro-etching → washing → pickling → copper plating → washing → acid leaching → tin plating → washing → lower plate.

NaOH solution was used to remove the plating resistant coating layer, so that the non-circuit copper layer was exposed.

Etching, which uses the chemical copper to react in order to remove non-circuit parts.

Printed characters on the circuit board, mainly pcb manufacturers information, product information, specific process: green oil final curium → cooling and static setting → mesh → printed characters → curium.

Gold-plated finger, a required thickness of nickel/gold is plated on the plug finger to make it harder and wear resistant.

Molding, through the mold stamping or CNC gong machine to the customer pcb prototype board shape required, molding method organic gong, beer board, gong, hand cut.

Test, mainly through the flying needle tester to test the circuit board, is not easy to find the open circuit, short circuit and other problems.

PCB Prototype Description

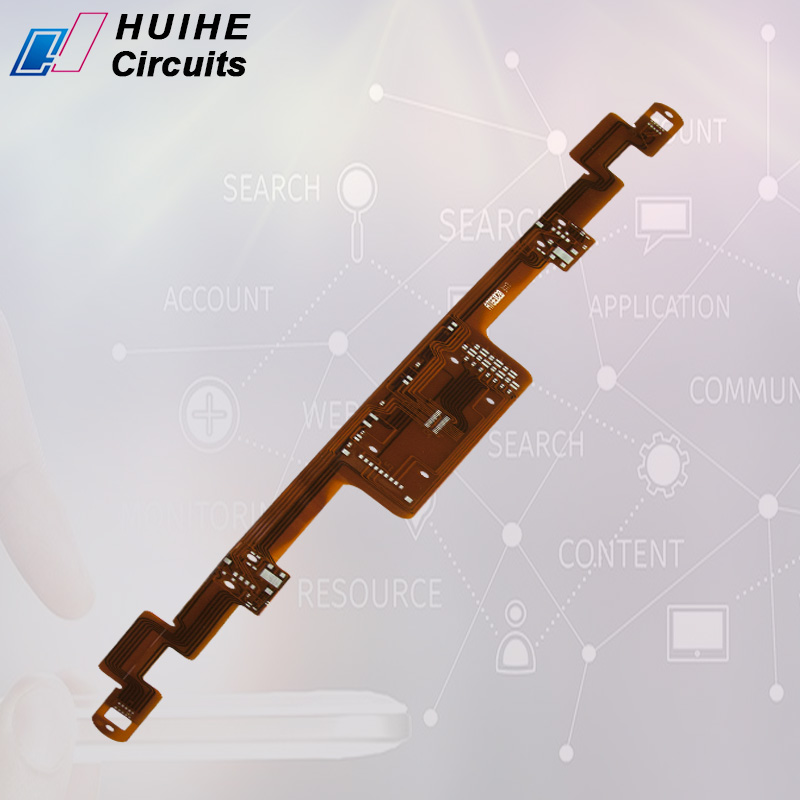

pcb prototype, pcb prototypes, pcb prototype board, pcb prototype service, pcb prototyper, pcb prototype fabrication service, 4 layer pcb prototype, quick turn pcb prototypes, pcb prototype assembly, china pcb prototype, free pcb prototype, pcb prototype usa, best pcb prototype service, cheap pcb prototype, custom pcb prototype, fast pcb prototype, flexible pcb prototype, low cost pcb prototype, pcb prototype quote, pcb prototype service usa, rigid flex pcb prototype, rogers pcb prototype, usa pcb prototype, flex pcb prototype,

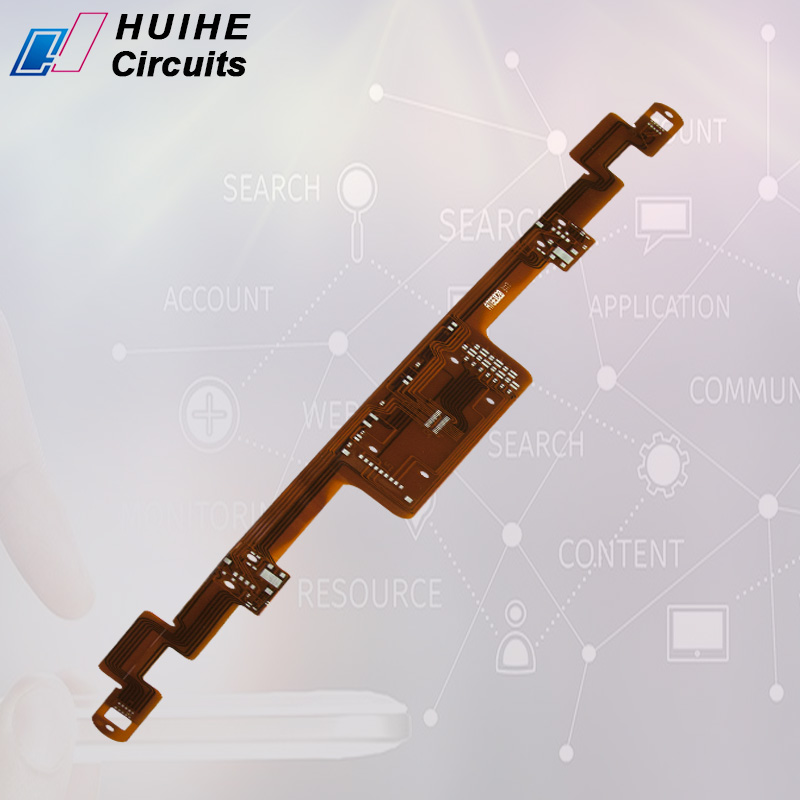

How to use PCB prototype board

PCB prototype refers to debugging the functions of pcb prototype before mass production, and then subsequent batch production. PCB prototype can avoid production risks and reduce production costs. Huihe circuit can process Flex PCB prototype, Military PCB prototype, Rogers PCB prototype, Rigid Flex PCB prototype, HDI PCB prototype prototype, Aluminum PCB prototype, Heavy Copper PCB prototype and other products.

China PCB prototype

When the customer performs PCB prototype, the quoter of huihe circuit will remind the customer to specify the quantity of PCB prototype. PCB prototype manufacturer will confirm the packaging of PCB prototype products, complete electrical inspection and additional services.

PCB Prototype Contents Related Articles

PCB Prototype Contents Random Article

china quick turn pcb assembly suppliers & factories

Quick turn PCB assembly (I) Accordi...

How To Choose PCB Prototype Manufacturers?

Before looking for manufacturers to...

Fast Turn PCB Prototype

What is Fast Turn PCB Prototype?Fas...

Flexible PCB Prototype Related Introduction

Flexible PCB Prototype Related Issu...

Fast PCB Prototype Services

Fast PCB Prototype TipsPCB design e...

What is cheap PCB prototype?

What is cheap PCBprototype?Cheap PC...

What is rigid flex PCB prototype?

What is rigid flex PCB prototypeRig...

PCB prototype services content

PCB prototype services basic princi...

PCB Prototype Article

Flexible PCB Prototype Related Introduction

Flexible PCB Prototype Related IntroductionPCB Prototype News

china quick turn pcb assembly suppliers & factories

china quick turn pcb assembly suppliers & factoriesPCB Prototype Tags

You May Also Like

Huihe PCB Site Information

- Article Statistics:191 Articles